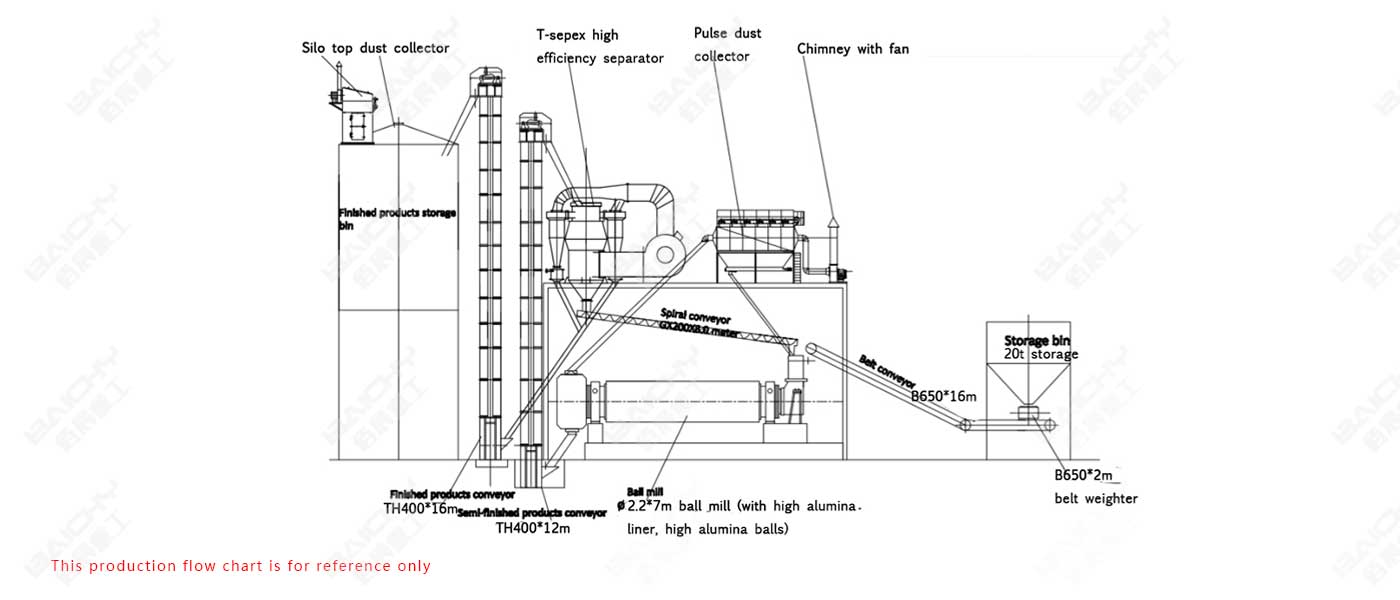

| Equipment list | Jaw crusher, Ceramic ball mill, Air classifier, Pulse dust collector, Bucket elevator, Belt conveyor and etc. |

| Raw materials | Feldspar, Quartz |

| Mohz hardness | 6.0-6.5 |

| Feeding size | <25mm |

| Capacity | 1-30tph |

| Output size | 200-425mesh |

| Application | glass, ceramic, fillers, enamel frits and glazes, construction industries and etc. |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Raymond mill (or suspension roller mill) is an efficient and energy-saving dry grinding equipment. It adopts a vertical structure and annular grinding principle. The material is crushed to 80-600 mesh (0.175-0.044mm) through the rolling action of the grinding roller and the grinding ring.

Working principle: The material enters the grinding area through the feeder, and the grinding roller presses the grinding ring under centrifugal force to achieve the crushing effect. The fine powder is separated and collected by the airflow classifier.

Typical structure: It consists of a main machine, an analyzer, a pipeline system, a cyclone powder collector, a motor, etc., and can be equipped with dust removal and noise reduction equipment.

Technical origin: It was invented by the Raymond Company in the United States in the early 20th century. After several upgrades, it has become the mainstream equipment for non-metallic mineral processing.

YGM high-pressure roller mill uses the principle of static pressure crushing to efficiently and finely crush materials. It is an efficient and energy-saving crushing equipment, widely used in mining, building materials, the chemical industry, metallurgy, and other industries.

YGM high-pressure roller mill can process a wide range of materials, including but not limited to quartz, feldspar, barite, fluorite, dolomite, garnet, silicon carbide, bauxite, zircon sand, marble, calcite, iron ore, phosphate rock, etc., with a Mohs hardness of no more than 9.3 and a humidity of less than 6%, more than 400 kinds of non-flammable and explosive materials.

MTW trapezoidal European version mill is designed by professional R&D engineers with great concentration on research and innovation based on the absorption of new European grinding technology and concepts, combined with long-term mill R&D experience, and integrated with a large number of customer feedback and suggestions. It is an upgraded product of the traditional Raymond mill, with mature technology and powerful functions. It is widely used in power, mining, metallurgy, chemical industry, steel, building materials, coal, and other industries, and has produced huge economic and social benefits.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery