In the development of Shanxi's rich dolomite mineral resources, deep processing technology is the key to increasing product added value. In response to the annual production of 1 million tons of dolomite powder processing needs, we customized an integrated "crushing + grinding" production line, using an internationally leading combination of process equipment to achieve efficient operation of the entire process from raw material coarse crushing to ultra-fine powder processing, helping enterprises reduce costs, increase efficiency, and achieve green transformation.

Core process flow and technical highlights of 100tph dolomite crushing + grinding production line

Crushing system: three-stage efficient crushing

1. Coarse crushing stage: ZSW9638 vibrating feeder evenly feeds to PE600x900 jaw crusher, with a processing capacity of 50-120t/h, compressive strength ≤320MPa, feed particle size ≤500mm, and discharge particle size ≤100mm.

2. Medium and fine crushing stage: equipped with two 300X1300 fine jaw crushers, using deep cavity crushing and frequency conversion adjustment technology, processing capacity 16-105t/h/unit, discharge port 20-90mm, finished product particle size uniform, meeting the feeding requirements of the grinding system.

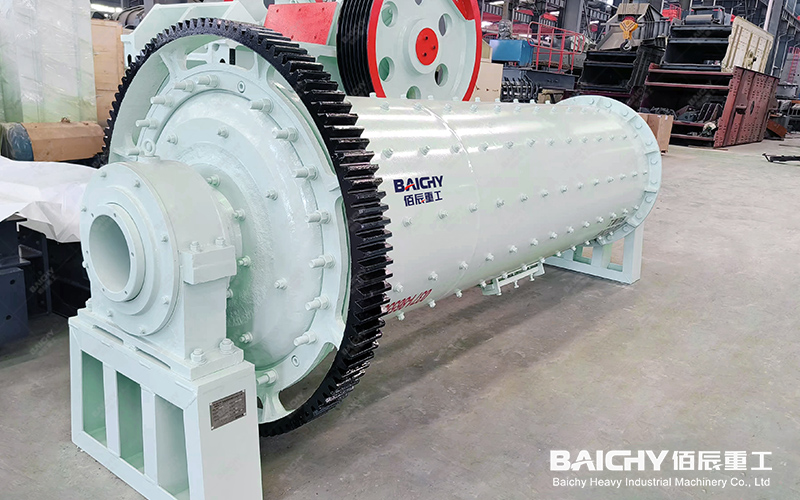

3. Grinding system: MTW175 European version grinding mill dual linkage

Each MTW175 grinding mill has a processing capacity of 10-35t/h, and the two machines can achieve a total production capacity of 60-70t/h in parallel. The finished product fineness is 80-325 mesh adjustable, supporting efficient grinding of carbonate minerals.

Adopting bevel gear transmission, arc air duct and pulse dust removal technology, the energy consumption is reduced by 30% compared with traditional grinding mills, and the dust emission is ≤10mg/m³, which meets the strict environmental protection control standards of Shanxi.

Analysis of the advantages of equipment selection for 100tph dolomite crushing + grinding production line

Jaw crusher + fine jaw crusher: reliability and economy

The PE600x900 jaw crusher is based on high manganese steel jaw plate and hydraulic adjustment system, with large crushing ratio and low maintenance cost, which is suitable for the medium and high hardness characteristics of Shanxi dolomite.

The 300X1300 fine jaw crusher adopts welded frame and wear-resistant alloy roller sleeve, which extends the service life by 1.5 times and adapts to continuous high-intensity operation.

MTW175 grinding mill: intelligent and energy-saving benchmark

Equipped with PLC automatic control system, real-time monitoring of grinding roller pressure, temperature and other parameters, reducing manual intervention and ensuring production stability.

The classifier has dynamic frequency conversion speed regulation, supports D97≤5μm ultrafine powder processing, and meets the needs of high value-added fields such as building materials and chemicals.

Adaptability design of the project landing in Shanxi

1. Environmental compliance: integrated pulse dust removal and silencer, dust and noise emissions are better than national standards, and meet the policy requirements of Shanxi's "Blue Sky Defense War".

2. Efficient utilization of resources: closed-loop design of the crushing system, raw material utilization rate ≥98%; grinding tailings can be recycled for roadbed materials, achieving zero waste.

3. Intelligent operation and maintenance: the remote monitoring platform tracks the equipment status in real time, and the fault warning response time is ≤30 minutes, ensuring continuous production in Shanxi mining areas.

Return on investment and industry value

1. Economic benefits: Taking a certain 600,000-ton annual output project in Shanxi as an example, the comprehensive power consumption of MTW175 dual-machine configuration is ≤25kWh/t, and the annual electricity bill savings exceed 1.5 million yuan.

2. Application scenarios: The finished powder can be widely used in refractory materials (200-325 mesh), ceramic glazes (800-1250 mesh), environmentally friendly desulfurizers (D90≤45μm) and other fields.

Conclusion: Create a new benchmark for Shanxi dolomite processing

This production line takes "high efficiency, energy ing, and intelligence" as its core, and provides a one-stop solution from crushing to ultra-fine powder for Shanxi dolomite resource development through the golden combination of ZSW9638+PE600x900+dual 300X1300+dual MTW175. Whether it is capacity improvement, cost control or environmental compliance, it sets a new benchmark in the industry and helps companies seize market opportunities!

Consult the customized solution now: To obtain exclusive process design, equipment quotation and investment return analysis, please contact the technical team (Tel: 0086 15093222637).