If you want to pulverize the crushed materials again for use in cement, silicate products, new building materials, refractory materials, non-ferrous metal beneficiation, and other industries, we must think of ball mills at this time.

Baichy has two types of ball mills to choose from dry ball mill and wet ball mill; If you don't know the process requirements, you don't know how to choose.

For example, a cement production line requires a dry ball mill.

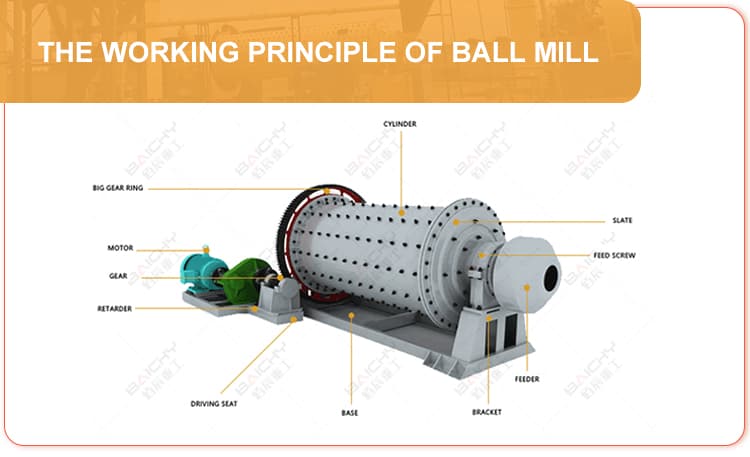

The ball mill consists of main parts such as the feeding part, discharging part, rotating part, transmission part (reducer, small transmission gear, motor, electric control), and so on.

Ball mill features

1. Smooth operation and reliable work. The downtime of the ball mill for maintenance is reduced and the efficiency is improved.

2. The hollow shaft is made of cast steel, the inner lining can be removed and replaced, the large rotary gear is processed by casting gear hobbing, and the cylinder is inlaid with a wear-resistant lining plate, which has good wear resistance.

3. According to the material and ore discharge method, a dry ball mill and the wet grid ball mill can be selected.

The working principle of the ball mill

When working, the material is loaded into the barrel by the hollow shaft at the feed end of the ball mill. When the ball mill barrel rotates, the grinding body is attached to the barrel liner and taken away by the barrel due to inertia, centrifugal force, and friction. When it is brought to a certain height, it is thrown down due to its gravity, and the falling grinding body crushes the material in the cylinder like a projectile. The material enters the first chamber of the ball mill uniformly and spirally from the feeding device through the feeding hollow shaft. There is a stepped lining plate or a corrugated lining plate in the chamber, and steel balls of different specifications are installed inside. The rotation of the cylinder generates centrifugal force to bring the steel balls to a certain height. Falling, pounding, and grinding the material. After the material reaches the rough grinding in the first warehouse, it enters the second warehouse through the single-layer partition board. The warehouse is inlaid with a flat-lining plate and has steel balls to further grind the material. The powder is discharged through the discharge grate to complete the grinding operation.