Double-toothed roll crusher market insights: 3 core pain points of India's crushing equipment demand

1. Efficiency and cost contradiction: Small and medium-sized mines have limited budgets, but traditional jaw crushers have high energy consumption and frequent maintenance (India's average electricity cost ≈ ₹8/kWh).

2. Environmental compliance pressure: In 2023, the Indian Central Pollution Control Board (CPCB) will mandate dust emissions of ≤50mg/Nm³, and non-compliant companies face high fines.

3. Lack of localized services: European brands have long delivery cycles (6-8 months) and Chinese brands have insufficient spare parts supply, affecting production continuity.

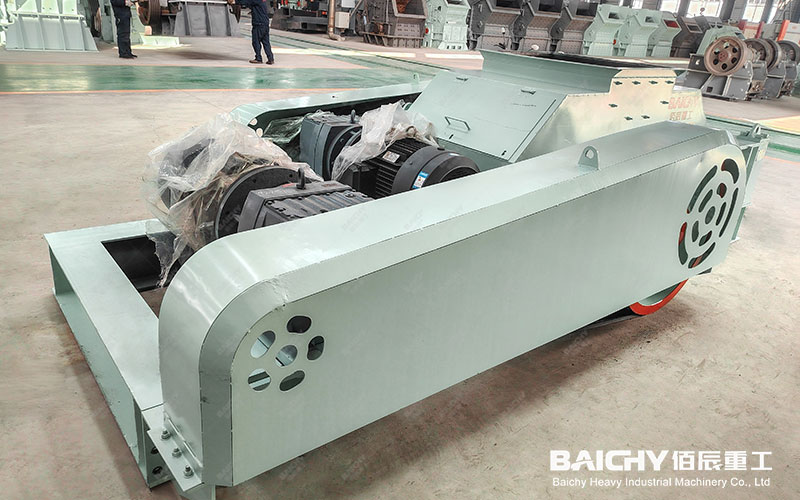

Breakthrough points of double-toothed roller crusher:

1. Structural adaptation: The double-roller differential design (main roller speed 50-60rpm, auxiliary roller speed 30-40rpm) realizes "shear + extrusion" dual crushing, reduces the over-crushing rate by 15%, and directly reduces the sticking problem of high-moisture coal in India.

2. Cost advantage: Unit energy consumption ≤0.5kW·h/ton, saving 20% of electricity costs compared to jaw crushers (based on a monthly processing of 50,000 tons, annual electricity savings ≈ ₹480,000).

3. Policy dividends: The equipment dust emission value is ≤30mg/Nm³, which meets the highest standards of CPCB and can apply for "green mining" government subsidies.

Double-tooth roller crusher product strategy: deep transformation from "functional parameters" to "scenario-based value"

1. Structural innovation is refined into customer benefits

Structural features Performance advantages Matching Indian customer pain points

| Structural features | Performance advantages | Matching Indian customers’ pain points |

| Adjustable tooth roller spacing (hydraulic adjustment) | Precise control of discharging particle size (2-200mm one-button adjustment) | The building materials industry needs to produce coarse aggregate (20-40mm) and fine aggregate (<10mm) at the same time, reducing the cost of secondary screening |

| Impact-resistant alloy steel tooth cap (removable) | Lifespan of up to 8000 hours, supports single tooth replacement | India’s high-silicon content ore wears quickly, reducing maintenance downtime by 50% |

| Intelligent overload protection system | Automatically reverse when encountering hard objects, motor damage rate ↓90% | The level of manual sorting in Indian mines is low, reducing unplanned downtime losses |

Double-tooth roller crusher application scenario deep binding

1. Coal industry: In view of the high soil content of Indian coal gangue, we launched the "wide pitch + high torque" model (such as DRC-1250H), with a processing capacity of 800t/h, suitable for customers such as Tata Power and Adani Group.

2. Construction waste recycling: In conjunction with the Indian smart city project, we provide "mobile double-toothed roller crushing station (tire/crawler version)", and the cost of converting construction waste into aggregates is 35% lower than that of purchasing from outside.

3. Iron ore pre-crushing: Design a "dry crushing + soil removal" solution for small and medium-sized mines in Odisha, replacing the traditional wet process and reducing water consumption by 80%.