Baichy Heavy Industrial Machinery is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales, mainly producing ball Mill,mobile crusher station,stone crusher machine,vibrating feeder,dewatering screen,belt conveyor,trommel screen,milling equipment,Jaw crusher,mobile crusher plant and other products. The company covers an area of 200,000 square meters, including standardized factory buildings, modern office buildings, R&D centers, sales and after-sales centers.

The company currently has more than 100 middle and senior technical personnel. Over the years, relying on professional technology, perfect scientific and quality management system (CE, ISO9001), high-quality products, Baichen Heavy Industry has rapidly grown into an important production and export base for China's mining machinery. Products are exported to more than 100 countries and regions such as Norway,France,United States,Spain,Germany,Dubai,Greece, Bulgaria,Singapore, and are widely used in Chemical,Coal,Bridge,Sand making,Construction works,Highway and other industries.

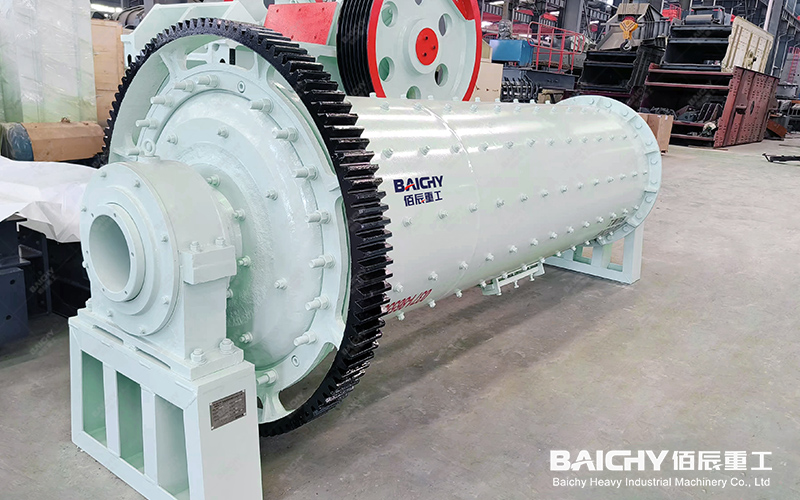

cement raw mill is one of our mining machinery. We introduce its detailed parameter information and the advantages of our company to you.

All our products are strictly in accordance with ISO/CE, affordable and unmatched quality.We pay attention to product quality, any goods defects, we will take responsibility. Provide OEM/ODM service. We have rich experience in export and project management, and can 100% ensure the safety of your order. Our cooperative customers are Sebelco,China Power Construction Corporation,Crec,China Communications Construction Corporation,Sinohydro Corporation,China Railway Construction Corporation, etc.

| Product Name | cement raw mill |

| Brand Name | Baichy |

| Place of Origin | Zhengzhou,China |

| Type | Mechanical |

| Condition | New |

| Material | Metal+Rubber |

| After-sale Service | Online technical support |

| MOQ | 1 |

| OEM/ODM | Yes |

| Packing | Carton |

| Application | Construction works,Coal,Highway...etc |

| Installation | Engineer Guide |

| Export Countries | United States,Sweden,Greece,Spain...etc |

| Factory visit | Welcomed Warmly |

| Payment | T/T,Western Union,Paypal...etc |

| Customization options | sample processing,graphic processing... |

Please note: The above table data is for reference only. For specific information, please contact us.

This is our factory