1.Raw material: wet sand

2.Capacity: 30ton per hour

3.Primary moisture 15%-20% content should be remove.

4.Dry moisture: 4.5-6tph of water.

Need heating: 3240-4320Mcal .Diesel 294-392kg/h.

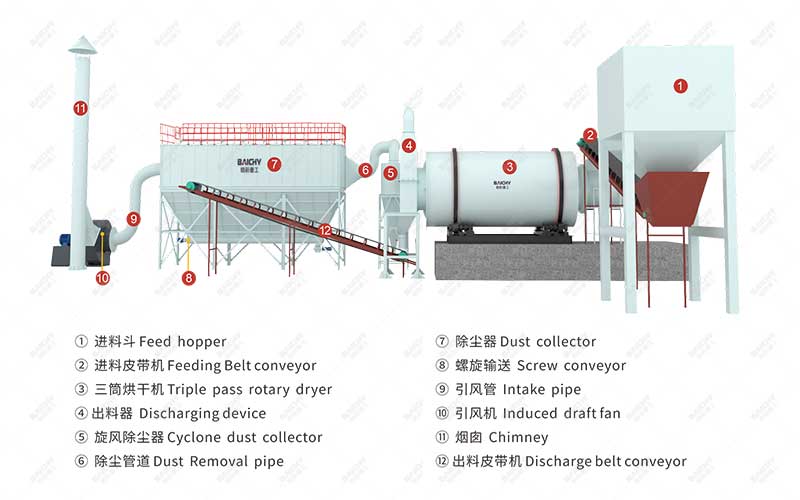

Triple pass rotary dryer Process introduction:

Wet material feed into the hopper by loader, then through vibrating feeder and belt conveyor transferred into dryer cylinder, where it comes into contact with the hot air generate by burner at high temperature and begins preliminary drying.

In the first cylinder the material undergoes preliminary heat exchange with the hot air, and most of the moisture in the material is evaporated. Subsequently, the material enters the second cylinder (second cylinder), where it comes into contact with the hot air at a slightly lower temperature, continues the drying process, and removes the remaining moisture.Finally, the material enters the outermost cylinder (third cylinder) and undergoes the final heat exchange with the hot air at a lower temperature but with a faster flow rate, ensuring that the material reaches the required degree of dryness.

| No. | Name | Specification | Power(kw) |

| 1 | Raw material Bin | Made by customer | / |

| Electrical magnet vibrating feeder | Model: GZG50-4 | 0.4x2 | |

| Slot size:500x1200 | |||

| Capacity : 50tph | |||

| feeding material evenly and continuously | |||

| 2 | Belt conveyor | B500x15m | 4 |

| 3+4 | Triple pass rotary dryer | Diameter:3m | 7.5x4 |

| Drum Length:7m | |||

| Capacity: 30-45tph | |||

| 5 | Cyclone collector system | Cyclone collector,pipes | / |

| 6+7+8+9+10+11 | Pulse dust collector with pipes, screwconveyor, induced fan,chimney | DMC240 | 37 |

| Total filter area:240m2 | |||

| Air: 14400-21600m3/h | |||

| Filter bag qty: 256bags | |||

| Filter bag size: 130x2500mm | |||

| With ID fan, power=45kw | |||

| (Y5-47-10D) Chimney, pipes | |||

| With discharge screw conveyor with rotary valve | |||

| 12 | Discharging belt conveyor | B500x15m | 4 |

| 13 | Diesel fuel burner | Electronic proportional | 11 |

| Heating: 3240-4320Mcal | |||

| Model: BNL 600 FC | |||

| 14 | Combustion chamber | Matching SIze: φ1700x4400mm | / |

| 15 | Electrical control Cabinet | Components: CHINT | 1 |

| Installed power for whole plant | |||

| Include dryer 4 pcs Motors VFD |

The three-drum dryer is not only suitable for drying various types of sand (such as river sand, sea sand, mountain sand, etc.), but can also be used to dry other granular materials (such as coal powder, mineral powder, etc.). This wide applicability makes the three-drum dryer valuable in many fields.