|

Equipment configuration

|

Hopper, ZSW960x3800 vibrating feeder, PE600x900 jaw crusher, CS110/PYB1200 cone crusher, 4yk1860 Vibrating screen, Belt conveyor. |

|

Raw materials

|

This stone-crushing plant can crush more than 120 kinds of ore materials such as limestone, granite, basalt, Riverstone, and rocks. |

|

Feed Size

|

Less than 500mm |

|

Capacity

|

100-150t/h |

|

Finished product

|

3-100mm |

|

Application

|

Produce aggregate of limestone, granite, basalt, river stone, marble, iron ore, dolomite, quartz, slag etc, which is widely applied for hydropower, construction, highway, railway, airport runway, civil engineering projects and etc. |

|

Advantages

|

High production efficiency and low operating cost; Large output, uniform particle size of finished stones and good grain shape, which meets the requirements of national high-speed materials. |

PF series impact crusher is a kind of equipment that uses the high-speed impact principle to crush various medium-hard materials with medium and fine crushing compressive strength not higher than 320Mpa, such as limestone, clinker, slag, coke, coal, etc.

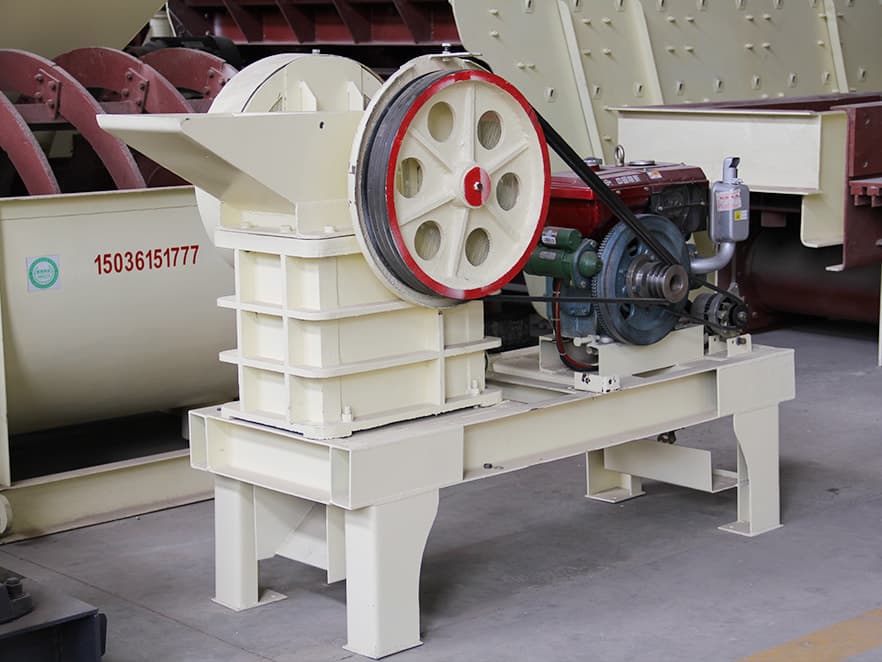

The jaw crusher is the preferred equipment for primary crushing. The output of the small jaw crusher is very small. If you don't need to process a lot of materials, a small jaw crusher can meet the demand. Its hot-selling models are PE200X350, PE250X400, and PE400X600.

The PE600×900 jaw crusher has a deep crushing cavity and no dead zone. This design improves the feeding capacity and output, making the PE600×900 jaw crusher perform well on the 100-150tph production line; new gasket discharge port The design makes the discharge particle size easy to adjust, increasing the flexibility of the equipment.

CS110 cone crusher or PYB1200 cone crusher is suitable for crushing various ores and rocks with medium and above medium hardness, meeting the needs of different industries for crushing equipment.

In a 100-150tph crushing production line, combining the advantages of a PE600×900 jaw crusher and CS110 or PYB1200 cone crusher can achieve efficient, stable, and environmentally friendly crushing operations. At the same time, according to specific material characteristics and production needs, equipment configuration and parameter settings can be flexibly adjusted to achieve the best crushing effect and economic benefits.

The four-combination mobile station is widely used in various engineering projects due to its high flexibility, customizability, and efficiency. It can quickly adapt to different working environments and needs, provide efficient and accurate crushing and screening services, and provide strong support for the smooth progress of various engineering projects.

Impact crushers - high-quality impactors, Rock Crushing & Screening Plants, Crushing And Screening Plant, Stone Crusher For Sale

Cone Crushing - High Capacity And Superior Quality. Long Working Life Of Quick-Wear Parts. Stone Crusher Rock Crushing Plant for Sale.