|

Equipment configuration

|

ZSW6025 Vibrating feeder, PE400x600 Jaw Crusher, PF1007 Impact Crusher, 3YK1548 Vibrating Screen, and belt conveyor |

|

Raw materials

|

This stone plant can crush more than 120 kinds of ore materials such as Feldspar, limestone, granite, basalt, Riverstone, and rocks. |

|

Feed Size

|

300mm |

|

Capacity

|

30-60t/h |

|

Finished product

|

60 mm and down |

|

Design requirements

|

1.The required production capacity 2.The type, hardness, and abrasiveness grade of the crushed material 3.the maximum size of the feed 4.The size of the desired final fraction |

In industrial production, belt conveyors can be used as the link between production machinery and equipment to form continuous production, so as to realize the continuity and automation of production links, improve productivity and reduce labor intensity.

The belt conveyor can be widely used in mining, metallurgy, coal, transportation, hydropower, and other departments to transport bulk materials or finished items.

The vibrating feeder refers to a kind of equipment that uniformly and continuously transports block or granular materials from the silo to the receiving device, and can continuously and evenly feed the crusher.

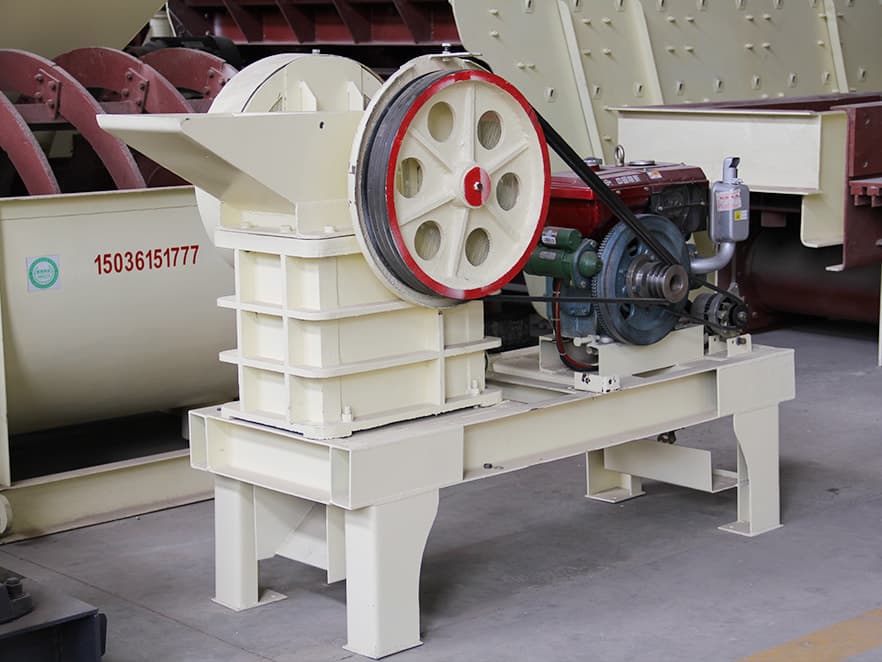

The jaw crusher is the preferred equipment for primary crushing. The output of the small jaw crusher is very small. If you don't need to process a lot of materials, a small jaw crusher can meet the demand. Its hot-selling models are PE200X350, PE250X400, and PE400X600.

The stone production line with an output of 30-50t/h is mainly composed of a pe400x600 jaw crusher, pf1007 impact crusher, 3YK1548 vibrating feeder, vibrating screen, belt conveyor, centralized electric control, and other equipment; in order to meet the different processing needs of customers, it can be equipped with PYB900 cone Crusher, dust removal equipment, etc. It can be used for aggregate and artificial sand making of hard limestone, granite, basalt, river pebbles, metallurgical slag, and other materials, and is suitable for applications in industries such as hydropower, building materials, highways, and urban construction.

The stone production line with an output of 30-60t/h has a high degree of automation, a large crushing ratio, high production efficiency, and a large processing capacity. The crushed products are in the shape of a cube, with low needle-like content, no internal cracks, and high compressive strength. The maintenance of the equipment is simple, and the wearing parts are made of the current domestic high-strength wear-resistant materials, with small losses and long service life, which can bring considerable economic benefits to customers.

The stone-crushing production line of Baichy Heavy Industry has been successfully applied to the crushing and processing of Feldspar, limestone, basalt, granite, pebbles, and other rocks. The quality of the crushed finished products fully meets the GB14685-2001 standard. Qualified aggregate.

The four-combination mobile station is widely used in various engineering projects due to its high flexibility, customizability, and efficiency. It can quickly adapt to different working environments and needs, provide efficient and accurate crushing and screening services, and provide strong support for the smooth progress of various engineering projects.

Impact crushers - high-quality impactors, Rock Crushing & Screening Plants, Crushing And Screening Plant, Stone Crusher For Sale

Cone Crushing - High Capacity And Superior Quality. Long Working Life Of Quick-Wear Parts. Stone Crusher Rock Crushing Plant for Sale.