|

Equipment configuration

|

Hopper, vibrating feeder ZSW850x3000, jaw crusher PE500x750, cone crusher CS75, vibrating screen YK1548 series, belt conveyor. |

|

Raw materials

|

Crush and screen limestone, marble, granite, basalt, river gravel and other hard stone materials. |

|

Feed Size

|

Less than 425mm |

|

Capacity

|

80-100t/h |

|

Finished product

|

3-100mm |

|

Application

|

Produce sand & gravels with various granularities of limestone, granite, basalt, river stone, marble, iron ore, dolomite, quartz, slag etc, which is widely applied for hydropower, construction, highway, railway, airport runway, civil engineering projects and etc. |

|

Advantages

|

High production efficiency and low operating cost; Large output, uniform particle size of finished stones and good grain shape, which meets the requirements of national high-speed materials. |

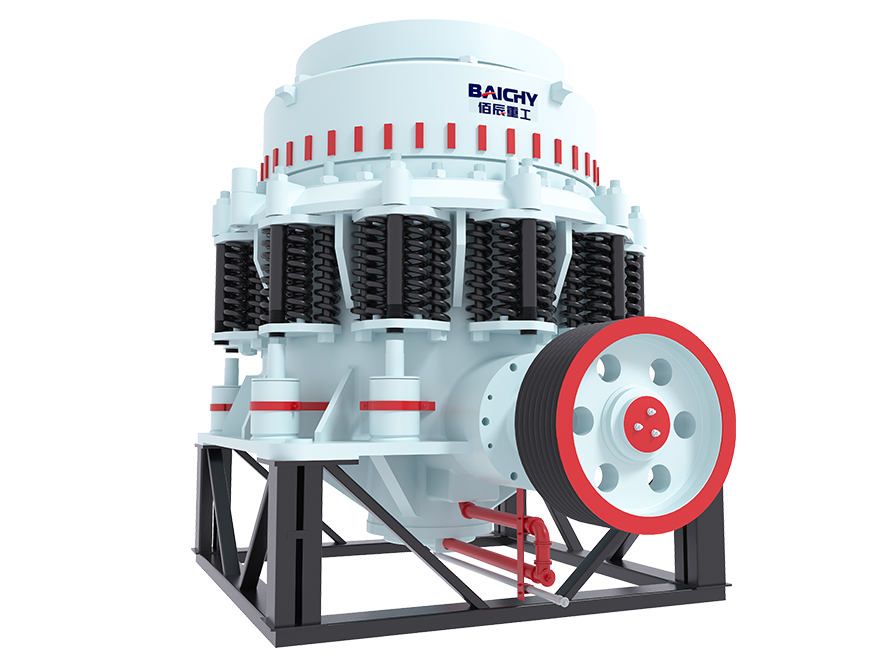

CS Symons cone crusher is a high-performance cone crusher. It is a modern high-performance crusher designed and developed based on the principle of laminated crushing and the concept of more crushing and less grinding, based on the introduction and absorption of foreign technology, according to customer needs.

In industrial production, belt conveyors can be used as the link between production machinery and equipment to form continuous production, so as to realize the continuity and automation of production links, improve productivity and reduce labor intensity.

The belt conveyor can be widely used in mining, metallurgy, coal, transportation, hydropower, and other departments to transport bulk materials or finished items.

YK series vibrating screens are widely used in quarries for screening sand and gravel, as well as product grading in industries such as coal dressing, ore dressing, building materials, power, and chemical industry. Its efficient and stable screening performance has been recognized by the majority of users.

Choosing a PE500x750 jaw crusher and CS75 cone crusher for the 80-100tph crushing production line can ensure the efficient, stable, and safe operation of the production line while reducing production costs and maintenance costs, and improving product quality and output.

The PE500x750 jaw crusher has stable performance and can work continuously for a long time. At the same time, it has low operating costs. It is equipped with automatic hydraulic overload protection and an automatic discharge device: when encountering unbreakable hard objects, the hydraulic system will automatically start and control The discharge opening is widened to allow hard objects to be discharged smoothly, thereby protecting the equipment from damage.

CS75 cone crusher has efficient crushing capacity and can meet the processing needs of 80-100tph production lines; in addition, according to production needs, you can choose CS75 cone crushers of different specifications, such as CSB75 and CSD75, to meet different discharge ranges and processing ability.

The four-combination mobile station is widely used in various engineering projects due to its high flexibility, customizability, and efficiency. It can quickly adapt to different working environments and needs, provide efficient and accurate crushing and screening services, and provide strong support for the smooth progress of various engineering projects.

Impact crushers - high-quality impactors, Rock Crushing & Screening Plants, Crushing And Screening Plant, Stone Crusher For Sale

Cone Crushing - High Capacity And Superior Quality. Long Working Life Of Quick-Wear Parts. Stone Crusher Rock Crushing Plant for Sale.