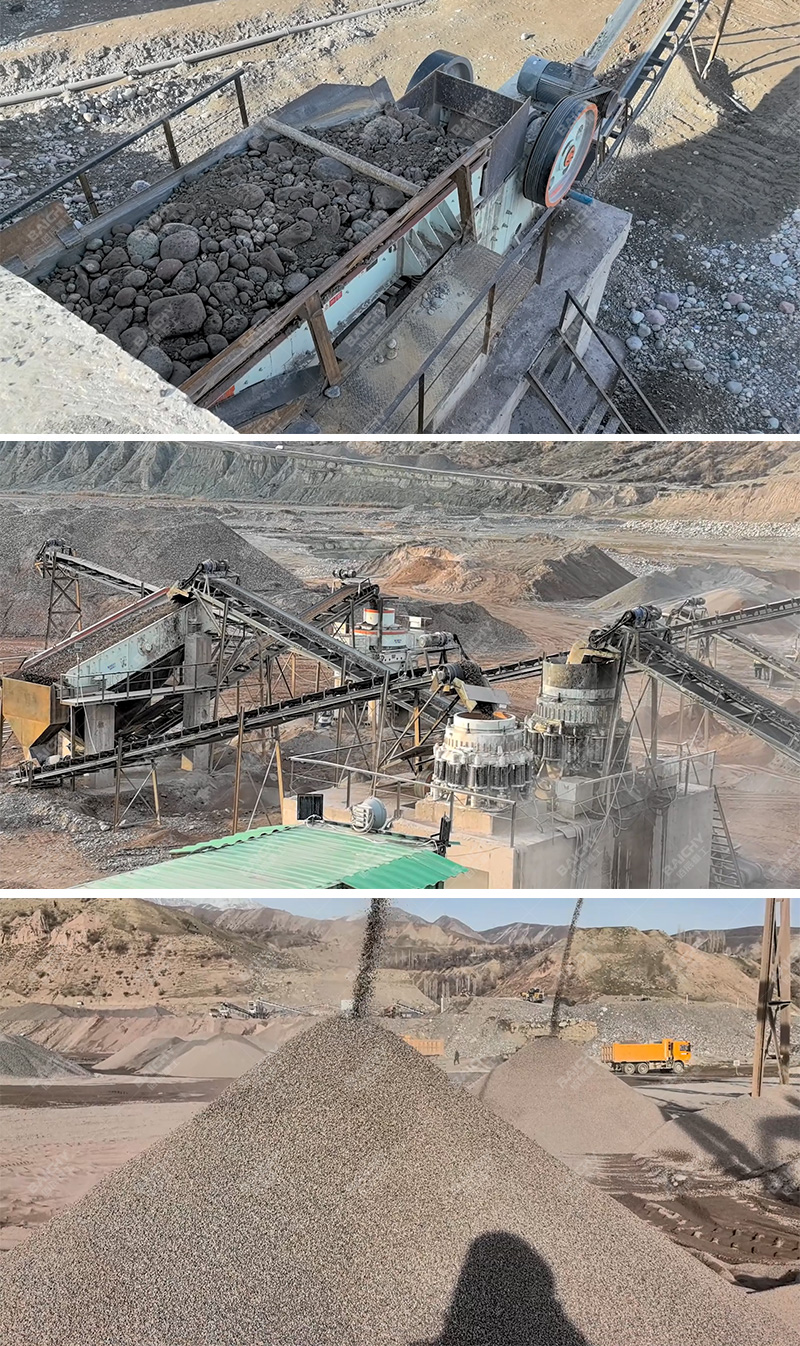

An andesite crushing production line with an output of 250 tph usually includes a series of equipment used to crush andesite from large pieces of raw materials into the required particle size. The following is a summary of the equipment that may be included in this production line based on common processes and equipment configurations:

Feeding equipment Vibrating feeder: used to feed the mined andesite raw materials into the jaw crusher evenly and continuously to ensure that the crusher can work stably and efficiently.

Coarse crushing equipment Jaw crusher: As the coarse crushing equipment of the production line, the jaw crusher has the characteristics of deep crushing cavity and reasonable structure, and can crush ores and rocks of various hardnesses with a compressive strength of less than 250MPa. It adopts the principle of extrusion crushing to crush large pieces of andesite into smaller particle sizes for subsequent crushing processing.

Medium crushing equipment Cone crusher: After coarse crushing, the andesite raw materials need to be crushed by cone crusher for secondary crushing to achieve finer particle size requirements. Cone crusher has the characteristics of high crushing efficiency and large crushing ratio, and is suitable for medium crushing operations.

Screening equipment Circular vibrating screen: used to screen the crushed andesite, send the qualified particle size materials to the next process, and return the unqualified ones to the cone crusher for re-crushing to ensure the uniform particle size of the crushed products.

Fine crushing and sand-making equipment Impact crusher or impact crusher: The impact crusher uses impact energy to crush materials, and the crushed materials are mostly cubic, which is suitable for the medium crushing of sand and gravel aggregates required for highways, municipal construction, etc. The impact crusher uses the principle of "stone hitting stone" for fine crushing, which can produce fine sand with uniform particle size and mostly cubic particle shape, which is suitable for the high-demand construction industry. According to the specific needs of the production line, one or two equipment can be selected for use in combination.

Cleaning and dehydration equipment Sand washing machine: used to clean the crushed andesite particles, remove the soil and impurities attached to the surface of the particles, and improve the quality and purity of the sand.

Dryer: Dehydrate and dry the cleaned andesite particles to ensure that the moisture content of the sand meets the requirements, which is convenient for subsequent use and storage.

Conveying equipment Belt conveyor: used to transport and connect materials between various processes to ensure the continuity and efficiency of the production line.

It should be noted that the specific equipment configuration and selection also need to be comprehensively considered based on the actual situation of the production line, raw material characteristics, product requirements, and investment budget. At the same time, equipment maintenance and maintenance are also the key to ensuring the stable operation of the production line and extending the service life of the equipment.

In addition, in actual operation, it is also necessary to pay attention to safety production and environmental protection requirements to ensure that the safety and environmental protection indicators in the production process meet the requirements.