12-gravel and 13-gravel refer to single-grain crushed stones with particle sizes of 10-20 mm and 16-31.5 mm, respectively. These two types of gravel are widely used in construction and engineering, and the main difference lies in the particle size and purpose. 12.

Particle size range

12-gravel: particle size between 10-20 mm.

13-gravel: particle size between 16-31.5 mm.

Uses of 12-gravel and 13-gravel

12-gravel: suitable for small, low-rise buildings and projects that require good slump and fluidity. For example, using 12-gravel in small buildings can provide good slump and safety. 23.

13-gravel: suitable for large buildings and large-area projects, such as building foundations, road foundation pouring, etc. Using 13-gravel in large projects can meet large-area requirements and strength. 23.

For the 200tph limestone mobile crushing production line, the following is a detailed analysis of its related content:

Overview of 200tph limestone mobile crushing production line

The limestone mobile crushing production line is a production line specially used for crushing, screening and processing limestone and other minerals with moderate hardness. The production line adopts a mobile design, has no restrictions on origin and time, and can be started anytime and anywhere, which is very suitable for occasions where the work site needs to be changed frequently.

200tph limestone mobile crushing production line equipment composition and function

Feeding equipment Common feeding equipment includes vibrating feeder, belt conveyor, etc. These equipment can feed large pieces of limestone into the crusher evenly and continuously, providing a stable supply of raw materials for subsequent crushing operations.

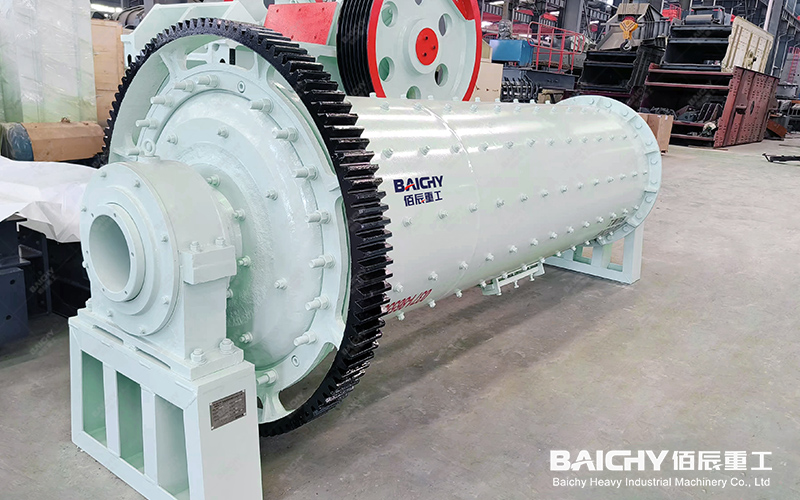

Crushing equipment Crushing equipment is the core part of the production line, which is used to crush large pieces of limestone into small particles. Common crushing equipment includes jaw crusher (suitable for coarse crushing operation), cone crusher (suitable for medium and fine crushing operation), etc. The jaw crusher crushes the large limestone into medium-sized particles, and the cone crusher further crushes the medium-sized particles into smaller particles.

Screening equipment Screening equipment is used to screen the crushed limestone and separate particles of different sizes. Common screening equipment includes vibrating screens, drum screens, etc.

These equipment can select appropriate screen specifications and screening methods according to production requirements, and collect particles of different sizes separately to meet the needs of limestone particle size in different industries.

Conveying equipment Conveying equipment is used to transport the crushed and screened limestone particles to subsequent processing links or storage sites.

Common conveying equipment includes belt conveyors, bucket elevators, etc. These equipment can select appropriate conveying methods and conveying speeds according to the needs of the production process to ensure smooth conveying and efficient production of limestone particles.

Control system Mobile crushers are usually equipped with a control system to monitor and control the operating status and working parameters of the equipment. Operators can start, stop, adjust and troubleshoot the crusher through the control system to achieve automatic control of the production line.

200tph limestone mobile crushing production line production process

Feeding: The raw materials are fed into the feed port of the mobile crusher through loading equipment such as loaders or excavators.

Crushing: After the raw materials enter the crushing chamber, the crushing system starts working. The breaker hammer impacts, hits and crushes the raw materials at high speed. The crushing plate guides and controls the particle size of the material.

Screening: The crushed materials are further screened by devices such as conveyor belts or vibrating screeners. The screened materials are divided into different particle sizes to meet different application requirements.

Transportation: The screened materials are transported to the next process link or storage area through equipment such as conveyor belts or stacking stackers.

Product features of 200tph limestone mobile crushing production line

Strong mobility The production line adopts a mobile design, which is convenient for transfer and installation at different work sites.

High degree of automation Equipped with advanced control systems to realize automatic control of the production line, reduce operating difficulty and labor costs.

High production efficiency Use efficient crushing and screening equipment to ensure that the production efficiency of the production line reaches 200tph.

The crushed limestone is screened by screening equipment to ensure uniform particle size and stable quality of the product.

Application areas of 200tph limestone mobile crushing production line

Limestone mobile crushing production line is widely used in construction, chemical industry, metallurgy and other fields to produce limestone particles of various sizes to meet the needs of different industries for limestone.

The 200tph limestone mobile crushing production line has the characteristics of strong mobility, high degree of automation, high production efficiency and uniform product particle size, which can meet the needs of different industries for limestone.

Related recommendations: Mobile Stone Crusher