Shale is a sedimentary rock with a fine texture, resulting from the compaction of silt and clay-sized mineral particles, which are commonly referred to as mud. Its defining feature is its layered structure, allowing it to be easily separated into thin sheets. The crucial step in producing shale oil, gas, and associated by-products is the crushing and grinding of shale. This process involves multiple stages, each requiring specialized machinery to achieve the desired reduction in particle size and prepare the shale for subsequent processing. Calcareous Shale Carbonaceous Shale Sandy Shale Siliceous Shale Shale Gravel

Shale Machines that crush and grind shale are used to reduce its size and prepare it for further processing. According to the requirements of shale crushing product granularity and output, there are coarse crushing equipment, medium crushing equipment, and fine crushing equipment to choose from.

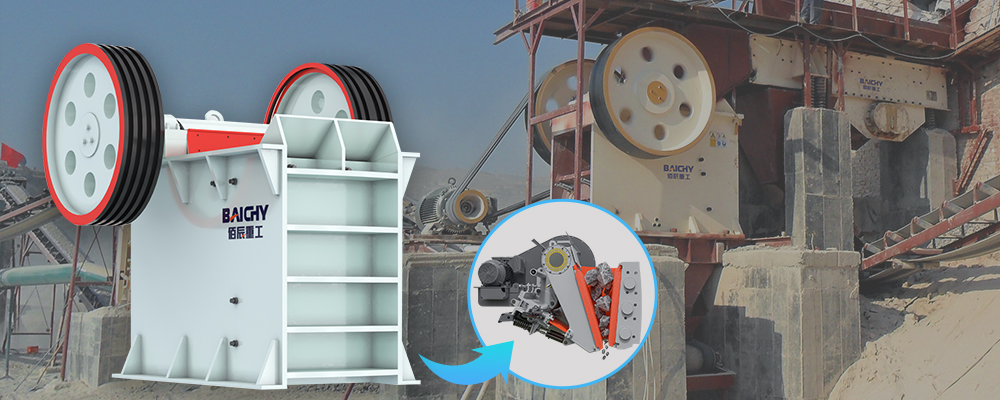

The Shale Jaw Crusher is a strong machine with two jaws, one fixed and one that moves. It's a crushing machine for the initial breaking down of large shale rocks. Jaw Crusher is perfect for breaking down big shale rocks into smaller, easier-to-handle pieces. The rocks get crushed between the jaws to make them the right size.

The PE Jaw Crusher is commonly used in industries like metallurgy, mining, chemicals, cement making, construction, heat-resistant materials, and ceramics.

The Shale Cone Crusher is a machine featuring a cone-shaped crushing surface and a concave surface. It's used for secondary and tertiary crushing to reduce the size of materials further. The material gets crushed when compressive forces are applied between the cone and concave surfaces.

This cone crusher is ideal for industries like cement mills, mining, construction, road and bridge building, railways, metallurgy, and more. It can handle hard materials such as iron ore, granite, limestone, quartzite, sandstone, and pebbles.

The Shale Hammer Crusher works with hammers attached to a spinning shaft. It's used to break up big pieces of shale, either as the first or second step of crushing. The hammers spin quickly and hit the material, breaking it up. Then, the broken pieces are thrown against metal plates inside the machine to break them down even more. This goes on until the shale is small enough to fit through the openings at the bottom of the crusher.

The Shale Hammer Crusher is good for turning large, solid rocks into smaller rocks. It's a cost-effective choice with a high capacity and crushing ability.

The Shale Impact Crusher relies on impact to crush materials. It's suitable for the secondary crushing of softer shale rocks. Material is fed into a chamber and hit by high-speed rotating hammers or blow bars, breaking it along natural cracks.

The PFW impact crusher is a popular choice for medium and fine crushing of medium-hard to soft materials, both domestically and internationally.

● Strong crushing capacity

The shale crusher adopts advanced crushing principles and structural design. Through the high-speed and high-torque motor drive, it realizes fast and efficient crushing of materials. At the same time, the unique crushing chamber design makes the impact force on the material more uniform during the crushing process, effectively improving the crushing efficiency and reducing energy consumption.

● Stable crushing performance

The shale crusher equipment uses high-quality wear-resistant materials and precision manufacturing technology to ensure that the equipment can maintain stable crushing performance during long-term operation. In addition, the equipment is equipped with an intelligent control system that can monitor the operating status of the equipment in real time, detect and handle potential problems in time, and ensure production continuity.

● Low grinding operation cost

The shale crusher adopts high-efficiency and energy-saving motors and transmission systems, reducing energy consumption. The equipment structure design is reasonable, reducing the wear and replacement frequency of vulnerable parts, and reducing maintenance costs. The equipment is easy to operate and maintain, reducing labor costs.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!