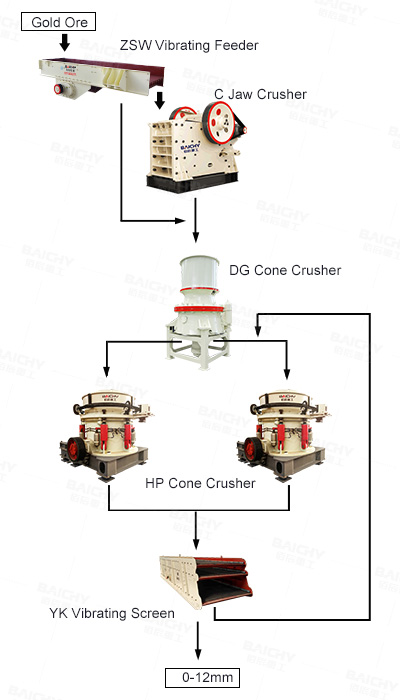

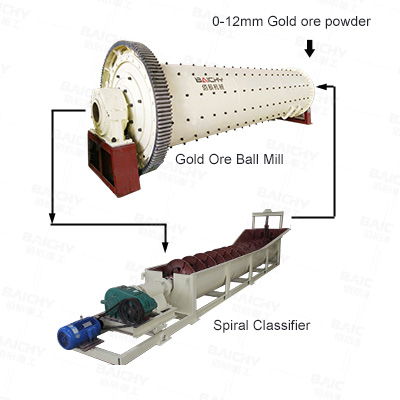

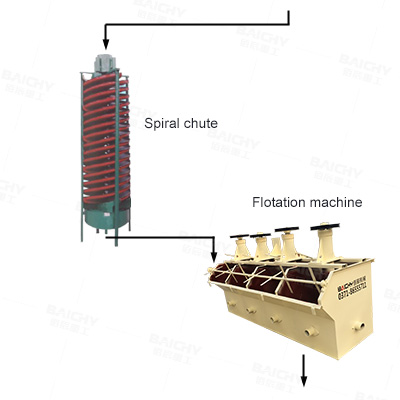

Gold ore is a mineral aggregate with sufficient gold content and can be used industrially; gold mine is a place where gold is obtained through mining operations; gold deposit is an accumulation of gold ore with a certain scale that can be used industrially through mineralization. The main types of gold ore are alluvial gold and vein gold. Gold is an important ornament as well as an ideal material in industry. The gold ore processing production process mainly includes three processes: crushing, grinding, and beneficiation. During the crushing process, three-stage closed-circuit crushing is more modern and suitable for crushing high-hardness gold ore, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding efficiency; during the grinding process, two-stage one-closed grinding is the most efficient The advanced grinding process can make the gold ore grind more fully; in the beneficiation process, the more successful new processes that have appeared in recent years are representative: gravity separation, amalgamation separation, cyanidation, flotation, etc. • Large pieces of gold ore are evenly sent to the jaw crusher or mobile jaw crushing plant (primary crushing) by the vibrating feeder through the silo for primary crushing; • The coarsely crushed gold ore is screened by a vibrating screen, and sent to a single-cylinder hydraulic cone crusher (secondary crushing) by a belt conveyor for secondary crushing; • The secondary crushed gold ore materials are sent to the multi-cylinder hydraulic cone crusher for fine crushing. Jaw Crusher is mainly used for medium-sized crushing of ores and bulk materials. It can crush materials with a compressive strength of up to 320Mpa and can be divided into coarse crushing and fine crushing. Baichy Machinery has PE and C series jaw crushers with complete product specifications. The feeding size is 125 mm~1020 mm, and the output of a single machine is ideally up to 800t/h. It is an ideal piece of equipment for primary crushing. Sturdy structure and stable performance: adopting the world's advanced technology, Baosteel's high-quality steel, heavy-duty eccentric shaft, and finite element analysis technology, it has a solid structure, stable performance, and long-term operation; Large crushing ratio, high output: heavy-duty grooved wheel and flywheel, optimized jaw plate, so that the crushing force is greater; "V" design makes the feeding port consistent with the actual situation, deep crushing cavity and no dead zone, higher output; Convenient operation, energy saving: hydraulic lubrication, wedge adjustment makes operation more convenient and flexible, lubrication is more convenient, single machine energy saving 15% to 30%, system energy saving more than double. DG series single-cylinder hydraulic cone crusher is widely used in the medium and fine crushing process of iron ore, gold ore, gold ore, and other metal mines. Baichen DG single-cylinder hydraulic cone crusher is a high-efficiency crusher designed by adopting advanced technology from the United States and combining the performance of high-quality materials in the industry. Sturdy structure and stable performance: adopting integrated frame castings, heavy-duty central shaft, both ends of the main shaft are supported, strong load-bearing capacity, large crushing force; advanced technology, stable operation, and long service life; Automatic control, easy operation: PCL touch screen operation and hydraulic adjustment of discharge mode are adopted, the discharge port is easy to adjust, and easy to maintain, and the removal and replacement of the fixed cone is more convenient and efficient, reducing downtime; DG series single-cylinder hydraulic cone crusher is widely used in the medium and fine crushing process of iron ore, gold ore, gold ore, and other metal mines. Baichen DG single-cylinder hydraulic cone crusher is a high-efficiency crusher designed by adopting advanced technology from the United States and combining the performance of high-quality materials in the industry. Sturdy structure and stable performance: adopting integrated frame castings, heavy-duty central shaft, both ends of the main shaft are supported, strong load-bearing capacity, large crushing force; advanced technology, stable operation, and long service life; Automatic control, easy operation: PCL touch screen operation and hydraulic adjustment of discharge mode are adopted, the discharge port is easy to adjust, and easy to maintain, and the removal and replacement of the fixed cone is more convenient and efficient, reducing downtime; The tire-type mobile crushing station is widely used in the mine crushing process. It can overcome the obstacles brought by the crushing site, environment, complicated basic configuration, and complicated logistics to the customer's crushing operation, and truly provide customers with efficient and low-cost project operation hardware facilities. Baichy Machinery tire-type mobile crusher has been successfully applied in mine crushing projects at home and abroad, playing a huge role. Flexible and cost-effective: vehicle-mounted traction, compact structure, stable and solid, suitable for working in harsh mountain environments, capable of crushing materials on site, and eliminating the intermediate link of transporting materials away from the work site for re-crushing, which greatly reduces The transportation cost of the material. Strong adaptability, customized on demand: the crushing station can be equipped with an independent generator set, even if the local power grid cannot be used, the machine can still work normally; at the same time, our company can carry out mobile crushing station according to the customer's site, material, grain type, and other requirements. Special order. The 0-12mm gold ore powder screened by the vibrating sieve is evenly sent to the ball mill for grinding, and sieved by the spiral classifier, and those that do not meet the requirements are sent to the ball mill to continue grinding; Ball mill is a commonly used and efficient grinding equipment. It is suitable for grinding ore such as iron ore, gold ore, copper ore, lead-zinc ore, and other metal beneficiation. It is used to grind the ore to below 0.075mm for the subsequent beneficiation process. According to different ore discharge methods, it can be divided into grid type and overflow type. Its grinding method can be divided into dry and wet grinding methods. Spiral classifier, referred to as a classifier, is one of the equipment for beneficiation. The spiral classifier is a kind of equipment for mechanical classification based on the principle that the specific gravity of solid particles is different, so the speed of sedimentation in the liquid is different. It can filter the material powder from the mill, then screw the coarse material into the feed port of the mill with the spiral blade, and discharge the filtered fine material from the overflow pipe. SF series flotation machine SF series flotation machines can self-suction air and pulp. The tank body is forward inclined, which is not easy to sink and is conducive to the forward return of foam; the use of double-blade impellers has a good stirring effect on the coarse sand at the bottom.Introduction of Gold Ore

Gold ore processing production process

Gold Ore Crushing and Screening

Gold ore grinding

Gold ore fines flotation

Have Any Questions!

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!