Aggregate is an indispensable component of concrete and mortar, and its performance and quality directly affect the strength and durability of concrete. Therefore, in concrete engineering, it is crucial to select the appropriate type and particle size of aggregate and control the quality of aggregate.

Common types of aggregates include coarse aggregate (particle size > 4.75mm), fine aggregate (0.06~ 4.75mm), commonly known as sand, gravel (4.75~20mm), and slag.

Baichy Heavy Industry's rich experience in turnkey crushing and screening equipment is one of its core competitiveness. With more than 20 years of industry experience, the company has accumulated deep expertise, technical strength, and market insight, and is able to provide customers with one-stop services from design, manufacturing, and installation to after-sales support.

Selecting the correct primary crushing equipment is critical when it is necessary to reduce rock or other material to a suitable size for aggregate applications. The right equipment can increase productivity, reduce costs, and produce an aggregate that meets the requirements of a specific application.

The feeding system is the starting link of the aggregate processing plant, which is mainly responsible for feeding raw materials (such as large stones, ores, etc.) into the production line. The system usually includes equipment such as feeders and conveyor belts, which can continuously and stably transport raw materials to the crusher to ensure the smooth operation of the production line. The design of the feeding system should take into account the nature of the raw materials, the production scale, and the processing capacity of the subsequent crusher to ensure the coordinated operation of the entire production line.

The crushing sand system is the core part of the aggregate processing plant, which is mainly responsible for crushing the raw materials into the required particle size. The system usually consists of multiple crushers, including a coarse crusher, medium crusher, and fine crusher (or sand-making machine). Coarse crushers are usually used to crush large pieces of raw materials into smaller particles for subsequent processing by crushers; medium crushers further crush the raw materials into smaller particles; fine crushers or sand-making machines are used to crush the raw materials into sand-like products. The selection of crushers should be comprehensively considered based on the nature of the raw materials, production scale, and product requirements.

During the crushing process, the crusher crushes the raw materials into the required particle size by extrusion, impact, and other methods. At the same time, in order to control the particle size distribution and shape of the product, it is also necessary to configure corresponding screening equipment to screen the crushed products.

The screening and sorting system is another important part of the aggregate processing plant. It is mainly responsible for screening and grading the crushed products according to the particle size. The system is usually composed of multiple screening equipment such as vibrating screens and drum screens, which can accurately screen according to the particle size requirements of the product. The design of the screening equipment should take into account factors such as screening efficiency, screening accuracy, and processing capacity to ensure the quality and output of the product.

During the screening process, the vibrating screen screens the material on the screen surface through vibration, so that materials of different particle sizes fall into different discharge ports. The drum screen screens the material by grade and classifies it through the rotating drum. The screened products can be further processed or stored as needed.

The sand washing system is a link used to clean sand in the aggregate processing plant. In the production process of sand and gravel aggregates, the sand often contains impurities such as soil and stone powder, which need to be cleaned by the sand washing system. The sand washing system is usually composed of sand washing machines, spiral sand washing machines, bucket sand washing machines, and other equipment, which can remove impurities in the sand by water washing to improve the quality of the sand.

The working principle of the sand washing machine is to wash and stir the sand with water flow to separate impurities from the sand. The spiral sand washing machine and the bucket sand washing machine further clean and classify the sand through the rotating spiral or bucket. The washed sand can be used in construction, roads and other fields, and has high economic value.

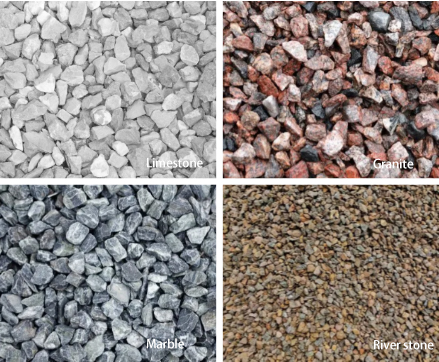

Pebbles are suitable for concrete that requires high fluidity; limestone, bluestone, river pebbles, granite, basalt, and other types of rocks. The particle size and gradation of crushed stone can be adjusted according to needs and are widely used in various concretes and mortars; slag: such as blast furnace slag, steel slag, etc., can be used as aggregate after crushing and screening; coal gangue aggregate has certain strength and durability; abandoned concrete blocks after crushing and screening can also be used as aggregate, called recycled aggregate.

In addition to the characteristics of the aggregate, the production capacity is also an important factor in the selection of crushing equipment. Manufacturers with high demand for production capacity need to choose equipment with larger capacity, while small-scale manufacturers can choose equipment with lower capacity to improve production efficiency and reduce costs.

In addition, equipment cost is also a factor that needs to be considered when choosing crushing equipment. The price of equipment of different specifications and models varies greatly, so it is necessary to make a trade-off and balance between production capacity and budget.

Finally, maintenance and maintenance costs are also one of the factors that need to be considered when choosing crushing equipment. Equipment maintenance and maintenance is an essential part of equipment operation, and the maintenance and maintenance costs required for different models and specifications of equipment are also different. Therefore, it is necessary to choose equipment that is easy to maintain and maintain to ensure the long-term stable operation of the equipment.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!