Mining crushing equipment can handle a variety of rocks, but the hardness of the rock is different, so Baichen Machinery designs different crushing equipment to crush materials according to the hardness characteristics of the rock.

Baichy's crushing equipment has different performance and characteristics.

So the question is, how can we choose the right stone crusher machine?

First of all, you need to understand the characteristics of rock materials. Different materials are suitable for different stone crusher machines; different outputs are suitable for different models.

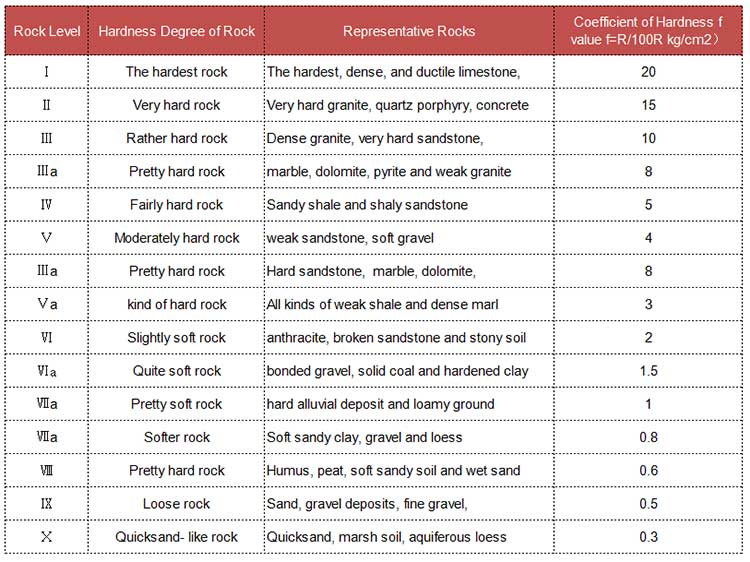

Classification of rock hardness

Through the above table, we can see the hardness of the material, and then we can choose the right crusher equipment for crushing according to the corresponding hardness.

What is the application of Baichy crushing equipment?

With high-quality steel casting and overwhelming reliability, the Stone crusher is widely as a primary and second crusher to crush hard stone, rock, granite, andesite, quartz, limestone in the sand, gravel, aggregates, or mineral processing industry.

Jaw crushers and cone crushers are suitable for the crushing of high hardness materials. If impact crushing equipment is used, it will cause serious wear, reduce equipment performance and shorten life.

You can see Baichy suggestions:

The wear-resistant parts of cone rock crushers are the rolled mortar wall and broken wall, generally made of Mn13Cr2 or Mn18Cr2 which makes up for the lack of toughness of the traditional high manganese steel. The casting has high hardness, good toughness, and long service life. Therefore, the cone crusher is also suitable for high hardness materials.

The impact crusher is not used because the toughness of its wear-resistant parts is weak. If the material with high hardness is broken, worn parts of this mining equipment need to be replaced frequently. The initial cost may be low, but later due to the frequent replacement of worn parts, the cost will continue to increase and the economic benefits will decrease.

When the material is medium hardness, such as gravel, jaw crusher equipment and impact crusher can be selected. Jaw crushers and cone crushers can also be used for medium hardness materials, but the cost will be high, especially cone crushers, so the above two kinds of equipment are not cost-effective for medium hardness or soft materials. Therefore, if you want to achieve the same crushing effect at an ideal economic cost, the impact crusher and the secondary crusher must be the best choice.

Sometimes Stone crusher can also be selected according to the raw materials size

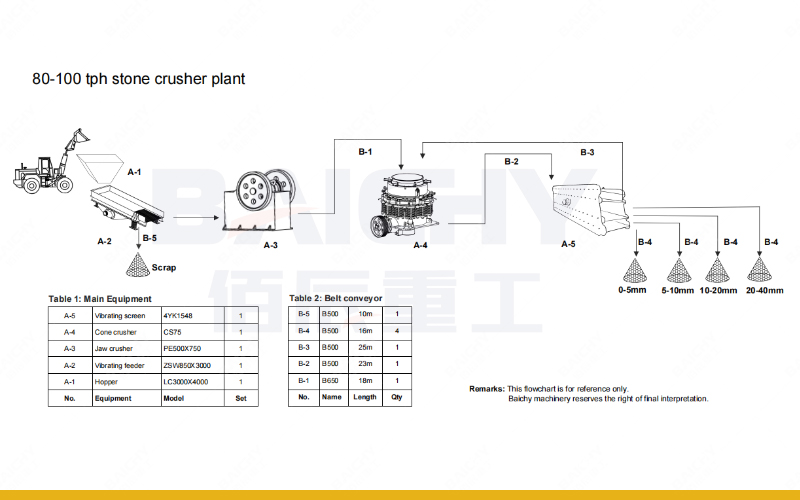

According to the particle size of the raw materials, we can divide the crushing process into four processes: coarse crushing, medium crushing, fine crushing and sand making. For coarse crushing, a jaw rock crusher is generally used. If the size of the material is larger than 210mm, the jaw rock crusher shall be selected to crush large pieces of material first. The impact crusher and cone crusher are generally used in medium crushing stage. For example, if the feed size of the material is less than 50mm, you can directly choose the secondary crusher.

Selecting a rock crushing equipment by production capacity

Through the above two steps, we can already determine what kind of equipment to choose, but each type of crushing equipment is divided into different models, including heavy, small, and mini crushing equipment. The choice of model depends on factors such as production capacity, feeding size, discharging size, and so on.