The 80-100 t/h sand and gravel production line belongs to the medium-sized sand and gravel crushing production line. It is a complete, efficient, and flexible production system, which is widely used in mining, construction, highway, railway, and other industries.

1. Composition of 80-100 tons/hour sand and gravel production line

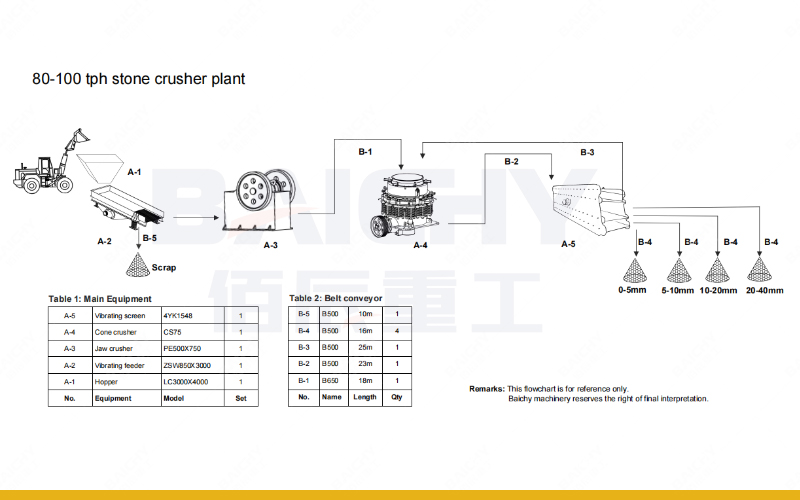

• Feeding equipment: such as a vibrating feeder, used to feed raw materials (such as large stones, stones, etc.) into the crushing equipment evenly and continuously.

• Crushing equipment:

Primary crushing: A jaw crusher (such as a PE600×900 jaw crusher) is often used to crush large pieces of raw materials and reduce particle size.

Intermediate crushing: According to the hardness of the raw materials and production requirements, impact crusher, cone crusher, etc. can be selected to further crush the raw materials.

Fine crushing: If finer finished products are required, fine crushing equipment such as sand making machine or fine crusher can be added.

Screening equipment: such as a vibrating screen, used to screen the crushed materials according to particle size to meet different production needs.

Conveying equipment: such as belt conveyors, is used to connect various equipment to achieve continuous material transportation.

Dust removal equipment (optional): such as bag dust collectors or pulse dust collectors, etc., is used to reduce dust pollution in the production process and improve environmental protection performance.

2. Features of 80-100 tons/hour sand and gravel production line

• High efficiency: The production line is reasonably designed, and the equipment cooperates closely, which can achieve efficient and continuous crushing operations.

• Flexibility: The configuration and parameters of each equipment can be adjusted according to production needs to meet the requirements of different raw materials and production scales.

• Environmental protection: Equipped with dust removal equipment to reduce dust pollution; at the same time, the noise and vibration generated during the crushing process are also effectively controlled.

• Intelligence: Some production lines are equipped with intelligent control systems, which can realize remote monitoring and automatic operation, reduce labor costs, and improve production efficiency.