Heavy hammer crusher has the advantages of a simple structure, high crushing ratio, high production efficiency, etc. It can be used in both wet and dry working conditions and is widely applied in the industries of mining, cement, coal, metallurgy, construction materials, highway, chemical industry, etc.

Heavy hammer crusher is a crushing device with strong crushing capacity, which is widely used in mining, building materials, roads, railways, water conservancy and chemical industries. It is mainly used to crush ores, rocks, construction waste and other materials of various hardness, especially for those occasions that require a larger crushing ratio and higher crushing efficiency.

Heavy hammer crusher is suitable for crushing various metal and non-metallic ores, such as iron ore, copper ore, gold ore, phosphate ore, limestone, granite, basalt, marble, etc.; it can also be used for crushing and screening of coal to improve the utilization rate of coal and product quality. At the same time, it can also be used to crush coke and other similar materials.

Heavy-duty hammer crusher is mainly applied in the industries of mines, metallurgy, building materials, road construction, railway building, water conservancy, cement, sand, coal, chemical engineering and electricity.

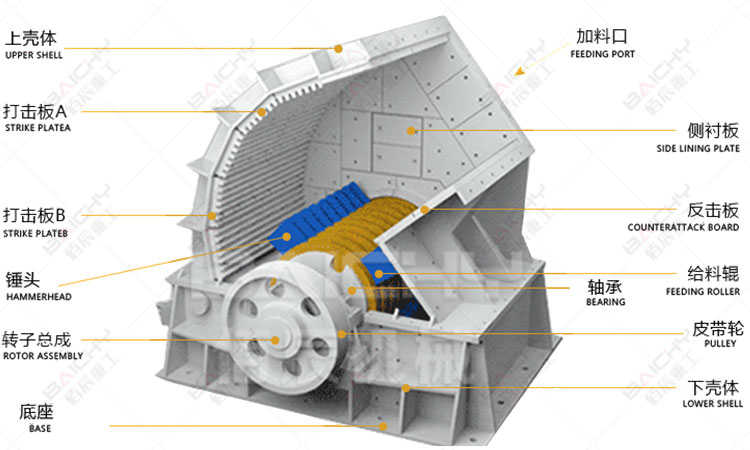

The main working part of the PCZ-type heavy hammer crusher is a rotor with a hammer (also called a hammerhead). The rotor consists of a main shaft, a disc, a pin, and a hammer.

The motor drives the rotor to rotate at high speed in the crushing chamber. The material is fed into the machine from the upper feeding port and crushed by the hammer. In the lower part of the rotor, a sieve plate is arranged, and the size of the crushed material smaller than the mesh size is discharged through the sieve plate, and the material larger than the mesh size is retained on the sieve plate and continues to be struck and ground by the hammer, and discharged through the sieve plate.

| Model | Feeding Size (W*L)(mm) |

Rotor Size (Dia.xL)(mm) |

Input Size(mm) | Power(KW) | Capacity(t/h) | Overall Dimension (mm) |

| PCZ0808 | 800 × 500 | Φ800 × 800 | ≤450 | 2 × 37 | 50-90 | 1760×1700×1540 |

| PCZ1308 | 850 × 800 | Φ1300 × 800 | ≤600 | 2 × 55 | 100-160 | 2818×2100×2390 |

| PCZ1310 | 1050 × 800 | Φ1310 × 1000 | ≤600 | 2 × 75 | 120-180 | 2818×2300×2390 |

| PCZ1510 | 1200 × 850 | Φ1500 × 990 | ≤700 | 2 × 132 | 160-210 | 3260×2370×2750 |

| PCZ1512 | 1200 × 1100 | Φ1500 × 1200 | ≤750 | 2 × 160 | 220-350 | 3260×2580×2750 |

| PCZ1615 | 1500 × 1300 | Φ1650 ×1500 | ≤1000 | 2 × 200 | 350-500 | 3456×2915×3185 |

| PCZ2016 | 1500 × 1400 | Φ2000 ×1500 | ≤1200 | 2 × 315 | 500-800 | 3880×2990×3560 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery