Raymond mill is a commonly used industrial grinding equipment, which has become a powder-making equipment widely used in mining, metallurgy, building materials, chemical industry, ceramics, power, and other industries.

Raymond Mill has many advantages such as high efficiency and energy saving, high and uniform finished product fineness, high screening rate, strong adaptability, easy operation, small footprint, good environmental performance, and a high degree of automation.

The particle size range of Raymond mill finished products is usually between 60-325 mesh (0.125 mm-0.044 mm), and the maximum fineness of some materials can reach 1000 mesh (0.013 mm).

Raymond mill is widely used in quartz, talc, marble, limestone, dolomite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, graphite, glass, manganese ore, titanium ore, copper ore, chromium ore, and other mineral industries.

Raymond Mill adopts an efficient grinding device and advanced powder separation technology, which can reduce energy consumption while ensuring output, thereby improving overall production efficiency.

By adjusting parameters such as the gap between the grinding roller and the grinding disc, wind speed, and feed amount, the fineness of the material can be accurately controlled to meet the requirements of powder fineness in different industries.

Compared with other grinding equipment, the screening rate of Raymond mill is usually higher, which means that more materials can pass through the screen at one time to become qualified products, reducing the number of repeated grinding and energy consumption.

Raymond mill is suitable for grinding a variety of materials, including ores of various hardness, non-metallic minerals, chemical raw materials, etc.

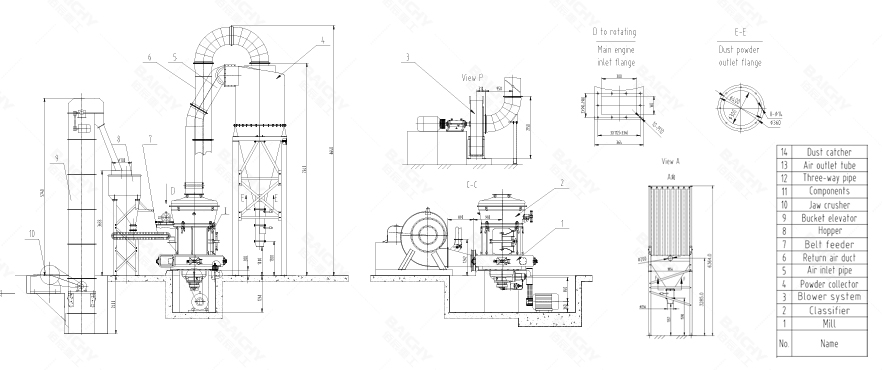

Step 1 The raw material is crushed into a specified particle size by the jaw crusher, lifted to the hopper by the bucket elevator, and then quantitatively sent to the crushing chamber by the feeder.

Step 2 A rotating shovel scoops up the ingredients and projects them between the rollers and the ring where the grinding takes place.

Step 3 The pulverized powder is blown into the classifier by the air blower for classification. Oversized particles fall into the grinding chamber for regrinding. Qualified powder flows into the cyclone collector through the classifier and is collected as finished product.

Step 4 To ensure that the Raymond mill works under negative pressure. The increased air flow enters the pulse dust collector through the pipeline, and is discharged into the atmosphere after purification. The dust-free operation in the workshop is realized through the pulse collector.

| Model | Roller | Roll Dia. (mm) | Roll Ring Size (mm) | Max. Input Size (mm) | Output Size (mm) | Capacity T/Shaft | Power (Kw) | Dimension | |

| 3R | 1510 | 3 | 150*100 | 570*100 | 15 | 0.125-0.044 | 0.8-10 | 7.5 | 3200*1200*3800 |

| 2115 | 3 | 210*150 | 630*150 | 15 | 0.125-0.044 | 1-12 | 15 | 3500*3300*4500 | |

| 2615 | 3 | 260*150 | 780*150 | 20 | 0.125-0.044 | 1.5-20 | 18.5 | 4650*3600*5100 | |

| 2715 | 3 | 270*150 | 830*150 | 20 | 0.125-0.044 | 2-28 | 22 | 4700*3600*5100 | |

| 3015 | 3 | 300*150 | 875*150 | 25 | 0.125-0.044 | 2-35 | 30 | 5300*4100*5200 | |

| 4R | 3016 | 4 | 300*160 | 890*160 | 25 | 0.125-0.044 | 3-36 | 30 | 5400*4100*5200 |

| 3216 | 4 | 320*160 | 970*160 | 25 | 0.125*0.044 | 4-45 | 37 | 7100*5900*7900 | |

| 3220 | 4 | 320*200 | 970*200 | 25 | 0.125-0.044 | 4-55 | 45 | 9900*5800*1058 | |

| 5R | 4119 | 5 | 410*190 | 1270*190 | 30 | 0.613-0.044 | 8-60 | 75 | 9200*7250*9700 |

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery