First of all, we need to know what the final product 0.2mm is like: Physical meaning: 0.2mm indicates the maximum allowable diameter of the particles (or the aperture through the sieve), that is, the size of all finished particles should be ≤0.2mm.

Definition of particle size standard

| Project | Parameter requirements | Test method |

| Target particle size | ≤0.2mm (D97≤0.2mm is more stringent) | ISO 3310 standard 80 mesh sieve |

| Allowable fluctuation | 70-80 mesh (ASTM E11) | Laser particle size analyzer auxiliary verification |

| Typical application | Building plaster/masonry gypsum | Screen pass rate ≥95% |

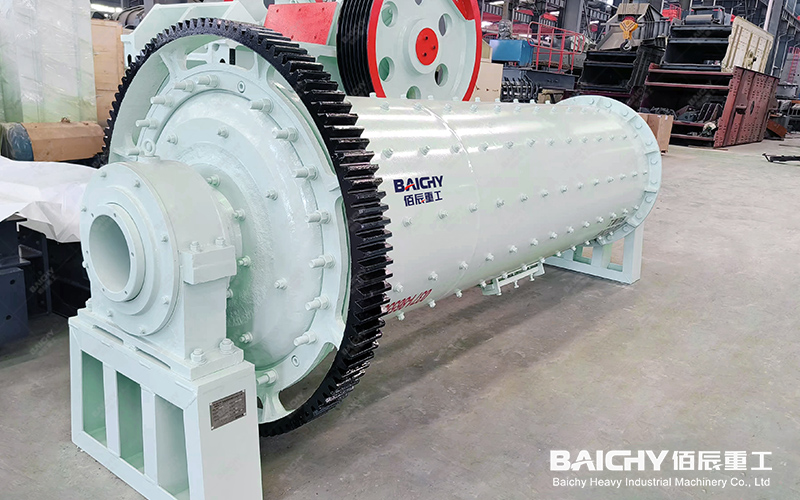

Baichy Heavy Industry's Raymond mill (YGM series) can usually meet the needs of 3tph (tons/hour) production capacity and 0.2mm (about 80 mesh) finished product particle size, but it needs to be confirmed in combination with specific models and technical parameters.

Baichy Heavy Industry's Raymond mill has a wide range of production capacity. When processing medium-hard materials (such as gypsum), by adjusting the roller pressure and fan speed, it can usually reach 3-10tph (depending on the material and fineness requirements).

Gypsum characteristics: Mohs hardness is about 2, easy to grind, and 3tph capacity is within the normal range for medium-sized Raymond mills.

0.2mm (about 80 mesh) is the typical fineness range of Raymond mills. The built-in turbine classifier can accurately control the discharge fineness (usually 80-400 mesh, i.e. 0.18-0.045mm). If a stricter particle size distribution is required, a secondary classification system (such as an airflow classifier) can be added.

Recommended models and configurations

YGM130 Raymond mill:

Capacity: 3-10tph (gypsum, about 3-5tph at 80 mesh).

Finished product fineness: 80-325 mesh (0.18-0.045mm).

Advantages: Energy-saving design, variable frequency control of the classifier, suitable for small and medium-sized production.

System matching

Pretreatment: Gypsum stone needs to be crushed to ≤25mm (jaw crusher is recommended).

Classification optimization: YGM's classifier is blade-type. If you need more precise control of fineness, you can consult Baichen whether it supports the installation of a turbine classifier (similar to the HC series).

Dust removal: It is recommended to use a pulse bag dust collector (to avoid gypsum powder dust).

Baichy Heavy Industry's YGM series Raymond mill can stably produce 0.2mm (80 mesh) gypsum powder with a production capacity of 3-10 tons/hour. It has a built-in partition classifier for precise fine control and supports partition and classification optimization. It is suitable for applications such as building plastering, masonry building formwork, etc., and provides urban crushing + powder metering solutions.

Why choose Baichy Heavy Industry?

1. Deep technical accumulation, industry leading

● 20 years of R&D experience: Focus on deep technology in the field of mining machinery, and accumulate rich industry insights and solutions.

● 56 patented technologies: Covering key links such as equipment design and production process, reflecting continuous innovation capabilities and technical barriers.

● Market-proven star products: PFL series equipment has sold more than 5,000 units worldwide, with stable and reliable performance to meet diversified production needs.

2. Guaranteed service, worry-free for customers

① Extremely fast response mechanism:

● Engineers provide 7×24-hour online technical support to solve emergencies as soon as possible.

● Any site in the world within 48 hours to minimize losses.

②Long-term cost advantage:

● Core components are guaranteed for one year to reduce the maintenance cost of young people.

● Accessories are supplied at cost price for life to eliminate the problem of price compensation for late replacement.

3. Globalization, adapting to extreme working conditions

● Covering 150+ countries and regions: including Southeast Asia, Africa, South America and other markets, the verification equipment is widely applicable.

● Extreme environment test: It can still operate stably under groundwater conditions such as high temperature, high humidity, and high special zone, and has strong technical reliability.

4. Full-cycle service support to help efficient operation

● From installation to training: Provide professional on-site guidance installation and worker operation training to ensure rapid production of equipment.

● After-sales system: Improve maintenance, technical upgrade support, long-term operation of efficient equipment, and extend service life.

● Rights protection: Directly connect through official channels (official website: http:www.baichychina.com/WhatsApp:+86 15093222637) to avoid intermediate risks and enjoy genuine services.