High-efficiency fine crusher, also known as fine crusher, new fine crusher, or third-generation sand-making machine, has reached the international leading level in performance and is the most effective, practical, and reliable stone crushing machine.

High-efficiency fine crusher has stable operation performance, simple structure, simplified process, and convenient maintenance.

Its large production capacity can meet the needs of large-scale production, and the hammerhead has a long service life, which reduces the replacement frequency and maintenance cost.

Compared with traditional fine crushers, high-efficiency fine crusher saves 50% energy, and the equipment is small in size and light in weight, which makes it easy to move and replace parts.

The investment of high-efficiency fine crusher is 35%-50% lower than that of traditional process equipment of the same scale, and the output efficiency is 35%-50% higher than that of traditional process equipment of the same scale.

Fine crushers are widely used in many fields, including mining, metallurgy, construction, chemical industry, pharmaceuticals, food, etc., and are used to process various ores, rocks, construction waste, chemical raw materials, pharmaceutical intermediates and other materials.

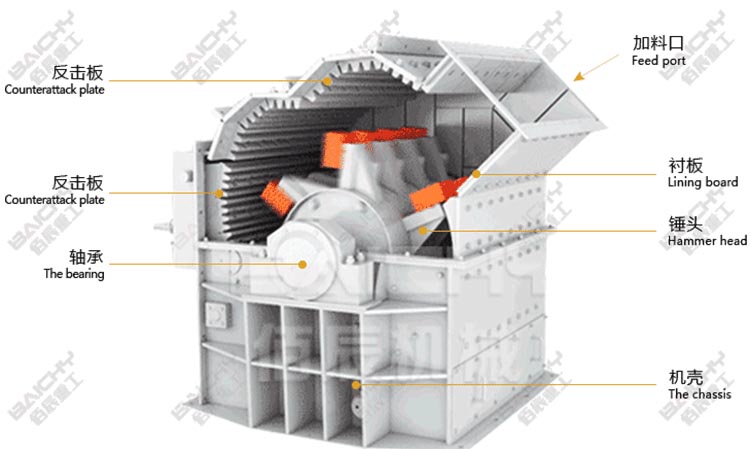

The working principle of the high-efficiency fine crusher mainly relies on the high-speed rotating hammer or blade to hit, cut and crush the material. The material enters the cavity through the feed hopper and is repeatedly hammered and cut by the high-speed rotating hammer or blade, thereby achieving the effect of fine crushing.

The high-efficiency fine crusher has a variety of technical parameters, such as high line speed, wear-resistant parts material, body structure, etc. These parameters work together to make the equipment have the characteristics of a high sand output rate and good quality finished sand. Taking limestone as an example, the particle size of the finished product is ≤5mm, accounting for more than 85%. The finished sand is cubic and has strong compressive resistance, which is suitable for high-standard construction needs.

| Model | Feeder Opening Size(mm) | Feeding Size(mm) | Output Size(mm) | Capacity of Cement(t/h) | Capacity of Limestone(t/h) | Motor Power(kw) |

| PCX-0804 | 400X185 | < 120 | < 3(85%) | 20-30 | 35-45 | 45 |

| PCX-0806 | 500X250 | < 180 | 35-40 | 45-55 | 55 | |

| PCX-0808 | 550X330 | 35-45 | 55-65 | 55 | ||

| PCX-1010 | 1000X350 | 45-55 | 65-75 | 75 | ||

| PCX-1210 | 1200X400 | 50-100 | 80-100 | 110 | ||

| PCX-1212 | 1200X450 | < 5(85%) | 90-110 | 100-110 | 132 | |

| PCX-1414 | 1500X500 | < 190 | 100-150 | 100-150 | 160 | |

| PCX-1616 | 1600X550 | 170-210 | 190-250 | 250 | ||

| PCX-1818 | 1800X800 | 250-270 | 280-310 | 315 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery