Mining dewatering screens play an important role in mining production due to their advantages of efficient dehydration, energy saving, and environmental protection, large processing capacity, simple structure, and strong adaptability.

Dewatering vibrating screen is a high-efficiency screening equipment that uses vibration force to achieve solid-liquid separation and dehydration.

Dewatering vibrating screens are widely used in mining, metallurgy, chemical industry, building materials, environmental protection, and other industries, mainly in coal preparation, ore dressing, electricity, sugar making, and other industrial sectors. It can efficiently process medium and fine particles, and realize multiple functions such as dry and wet classification, dehydration, de-medium, and desludging.

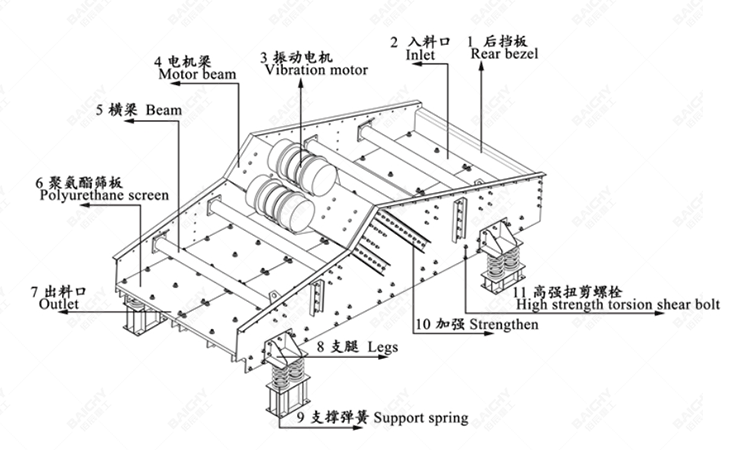

Dewatering vibrating screen is mainly composed of a screen box, screen, vibration motor, exciter, damping spring, and bracket.

The dewatering vibrating screen uses the exciting force generated by the vibration motor to make the screen body vibrate periodically in the direction of the exciting force. The material vibrates on the screen surface with the screen. Due to the gravity of the material itself and the vibration of the screen, the material is thrown up on the screen surface and produces a jumping motion to achieve separation.

Tailings treatment: including iron tailings, gold tailings, copper tailings, lead-zinc tailings, graphite tailings, etc. The vibrating dewatering screen can effectively remove moisture from tailings and improve the dry discharge efficiency of tailings.

Non-metallic minerals: such as quartz sand, zircon sand, glass sand, building sand, casting sand, building material sand, potassium feldspar, etc.

Dewatering vibrating screen is used for sand washing mountain sand. Through vibration screening, impurities such as soil and stone powder in mountain sand can be removed, and excess water can be removed at the same time, improving the quality and selling price of sand and gravel.

The dewatering vibrating screen is used in conjunction with the thickener to effectively remove moisture from the tailings and achieve dry discharge of the tailings.

The application of dewatering vibrating screens is very extensive, involving many industries and fields. It is mainly used to achieve solid-liquid separation, dehydration, desludging, and de-mediation of materials.

Mine dewatering screens usually consist of key components such as screen boxes, vibrators, screens, and damping springs. When the equipment is started, the vibrator drives the screen to vibrate at high frequencies. Materials are evenly placed on the screen and are affected by vibration and gravity.

| Model | Motor Power(kw) | Capacity(t/h) | Feeder Size(mm) | Sieve plate parameters | Overall Dimension(mm) | |

|---|---|---|---|---|---|---|

| Size(mm) | Area(㎡) | |||||

| ZSD1230 | 1.9 | 30-80 | ≤10 | 1200x3000 | 3.6 | 3085x1590x1439 |

| ZSD1236 | 2.2 | 30-80 | ≤10 | 1200x3600 | 4.32 | 3677x1590x1600 |

| ZSD1530 | 2.2 | 80-120 | ≤10 | 1500×3000 | 4.5 | 3075×2491×1601 |

| ZSD1536 | 3 | 80-120 | ≤10 | 1500×3600 | 5.4 | 3200×2491×1802 |

| ZSD1836 | 7.5 | 100-140 | ≤10 | 1800×3600 | 6.48 | 3758×3075×1988 |

| ZSD1842 | 7.5 | 100-140 | ≤10 | 1800×4200 | 7.56 | 4368×3075×2000 |

| ZSD1848 | 7.5 | 100-140 | ≤10 | 1800×4800 | 8.64 | 4791×3065×1959 |

| ZSD2442 | 11 | 140-180 | ≤10 | 2400×4200 | 10.1 | 4403×3737×1931 |

| ZSD2448 | 11 | 140-180 | ≤10 | 2400×4800 | 11.52 | 5008×3737×1977 |

| ZSD3048 | 15 | 200-250 | ≤10 | 3000×4800 | 14.4 | 4959×4518×2218 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery