The production capacity is required to be 20-25t/h, the feed size is 30mm, and the discharge size is 200 mesh; the equipment is required to operate stably, and the finished product particle size is uniform and fine, ensuring that the production efficiency and output meet the requirements; the recommended equipment is MTW European version trapezoidal grinding mill.

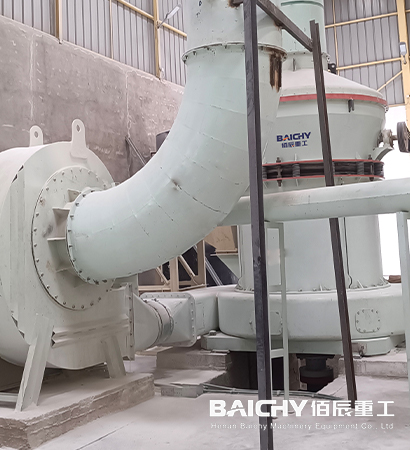

The MTW175 European version trapezoidal grinding mill is selected, and its finished product output range is 10-35T/h, which matches the design capacity of the production line. The mill has a forced turbine classification system, which can make the finished product particle size range reach 80-800 mesh, meeting the different fineness requirements of gypsum powder.

Including crushers, such as PE jaw crushers, PC hammer crushers, or PF impact crushers, etc., which are used to crush large-sized gypsum ore into small particles less than 30mm for subsequent processing.

Equipment such as hoists and screw conveyors are used to transport the raw gypsum from the crushing system to the grinding mill and to transport the ground gypsum raw powder to the calcining system.