The raw material is manganese ore, the feed size is 200mm, the discharge size is 200 mesh, and the output is 5-8tph. The powder is required to be uniform and fine, the equipment is energy-saving and environmentally friendly, and the operation is stable.

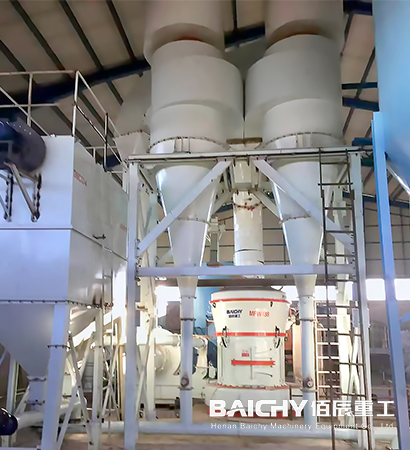

According to customer requirements, Baichen Machinery recommends the use of an MTW138 trapezoidal mill to process manganese ore. The whole set of equipment is mainly composed of the main machine, powder selector, fan, jaw crusher, bucket elevator, electromagnetic vibrating feeder, storage bin, bag dust collector, pipeline device, cyclone powder collector, electric control cabinet, motor, etc.

MTW138 trapezoidal mill is a kind of European trapezoidal mill, belonging to the MTW series, with the characteristics of high efficiency, energy saving and environmental protection.

MTW138 trapezoidal mill is widely used in power, mining, metallurgy, chemical industry, steel, building materials, coal and other industries, especially suitable for grinding various non-flammable and explosive mineral materials with Mohs hardness below 9 and humidity below 6%.

Most of Iran's manganese ores are coarse-grained, with a clear boundary between manganese ore and gangue, and a large difference in specific gravity. The MTW138 trapezoidal mill can effectively grind this type of ore to meet the needs of Iran's manganese ore processing.

The MTW Trapezoidal Grinding Mill performs well in the grinding process of limestone, calcite, dolomite, barite, talc, calcium carbonate, gypsum, bentonite, and other materials. This shows that it has a wide range of adaptability and can meet the grinding needs of various non-metallic minerals.

The MTW138 trapezoidal mill has significant advantages in processing manganese ore. Its high efficiency, environmental protection, easy operation, and maintenance make this equipment an ideal choice in the field of manganese ore processing.

Iran's requirements for environmental protection are becoming increasingly stringent. The environmental protection characteristics of the MTW138 trapezoidal mill meet Iran's environmental protection policy requirements and are conducive to the sustainable development of enterprises.