When choosing a 2-stage or 3-stage crusher in a quarry, you need to consider a number of factors, including raw material characteristics, production requirements, equipment performance, maintenance costs, and economic benefits.

Should we choose 2-stage or 3-stage crushing? This is a question we are often asked!

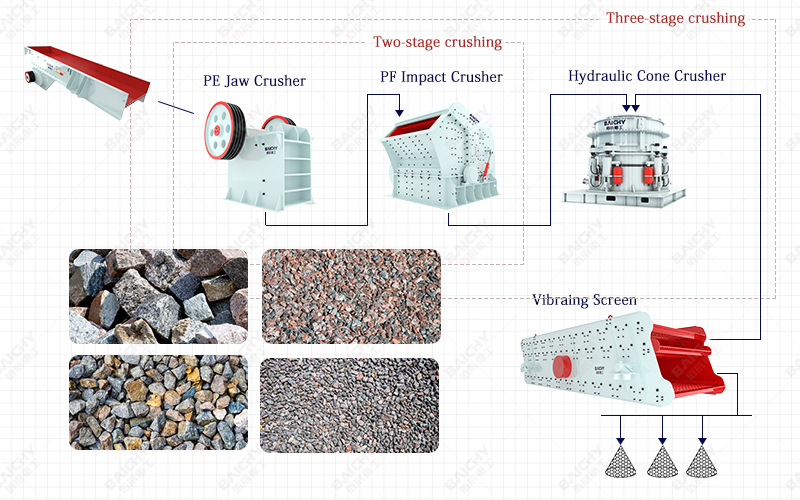

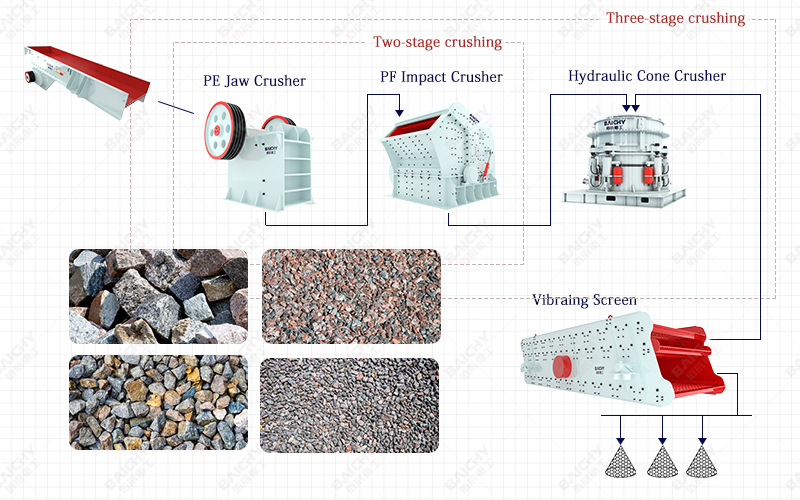

Secondary crushing involves 2 crushers in the crushing plant, namely the

primary crusher and the secondary crusher. This is usually a

jaw crusher and a

cone crusher, but not always. Sometimes it may be a jaw crusher and a cone crusher, depending on the characteristics of the material.

So how should we choose secondary or tertiary crushing?

1. Understand the raw material characteristics

• Rock hardness: Different types of rocks have different hardness, which directly affects the choice of crusher and the crushing efficiency. For rocks with higher hardness, you need to choose a crusher with a stronger crushing capacity.

• Rock composition: Some rocks may contain more impurities or sticky substances, which will affect the crushing effect and wear of the crusher.

2. Need to clarify production needs

• Output requirements: According to the production scale and target output of the quarry, select the appropriate crusher model and quantity.

• Finished product particle size: Different applications have different requirements for finished product particle size. It is necessary to select the appropriate crusher type and crushing stage according to actual needs.

3. Consider equipment performance

• Crushing ratio: Crushing ratio refers to the ratio of the crusher feed port size to the discharge port size, which reflects the crushing capacity of the crusher. When selecting a crusher, it is necessary to determine the required crushing ratio based on actual crushing needs.

• Processing capacity: Processing capacity refers to the amount of material that the crusher can process per hour. When selecting a crusher, it is necessary to ensure that the processing capacity of the equipment can meet production needs.

• Wear resistance: The wear resistance of the crusher directly affects the service life and maintenance cost of the equipment. When selecting a crusher, it is necessary to consider factors such as the material and manufacturing process of its wear-resistant parts.

When selecting a 2-stage or 3-stage crusher, it is necessary to comprehensively consider and weigh multiple factors such as raw material characteristics, production needs, equipment performance, maintenance costs, and economic benefits.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.