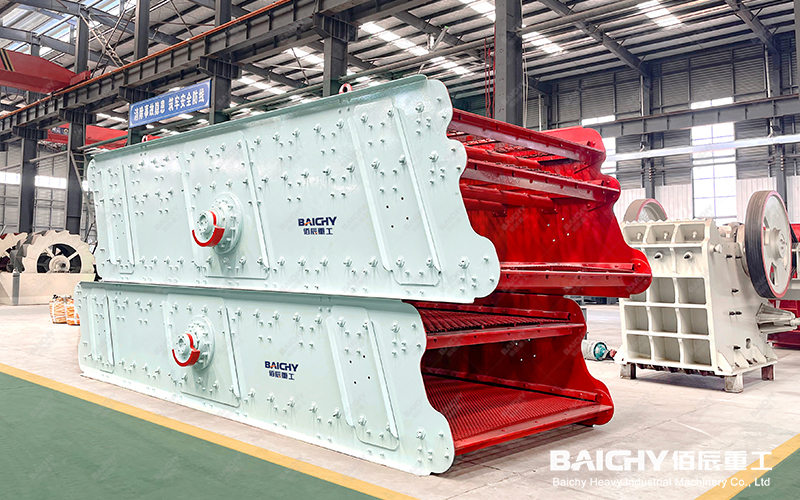

3YK2460 vibrating screen is a new type of multi-layer and efficient vibrating screening equipment. Its motion trajectory is approximately circular, so it is also called circular vibrating screen. The equipment is widely used in mining, coal, metallurgy, building materials and other industries for grading and screening materials.

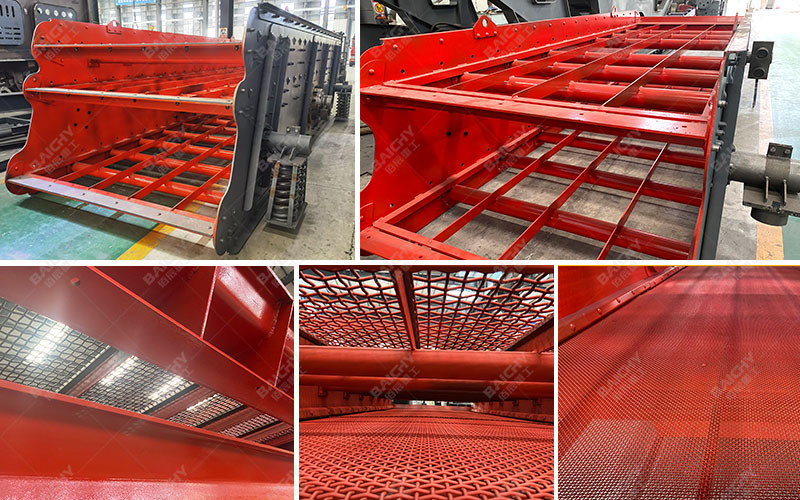

3YK2460 vibrating screen has three layers of wire mesh, and the top layer is 20mm, the middle layer is 10mm, and the bottom layer is 5mm.

3YK2460 vibrating screen Equipment features

• High screening efficiency: 3YK2460 vibrating screen adopts a three-layer wire mesh design, each layer of wire mesh has different specifications, and can screen three materials of different particle sizes at the same time, greatly improving the screening efficiency.

• Strong structure: The equipment adopts block eccentric exciter and tire coupling to increase the service life of the equipment. At the same time, the configured spring vibration reduction device can effectively reduce the impact force on the foundation and reduce vibration noise.

• Easy operation: The equipment starts smoothly, and the amplitude and frequency can be adjusted according to actual needs to achieve the best screening effect. The operation process is simple and easy to understand, which is convenient for users to carry out daily maintenance and upkeep.

3YK2460 vibrating screen Technical parameters

• Screen surface specifications: The specifications of each layer of screen are 2400*6000 mm, the single layer area is 14.4 square meters, and the total area is 43.2 square meters.

• Number of screen layers: three layers, the top screen aperture is 20mm, the middle screen aperture is 10mm, and the bottom screen aperture is 5mm.

• Processing capacity: According to the power and operating status of the equipment, the processing capacity can reach 620 tons (high power) or 70 tons (low power) per hour. The specific processing capacity also needs to be considered comprehensively according to factors such as material properties and screening requirements.

• Other parameters: such as speed, vibration frequency, double amplitude, maximum feed size, etc., vary from manufacturer to manufacturer and model. For specific parameters, please refer to the equipment manual or consult the manufacturer's customer service.

3YK2460 vibrating screen Precautions for use

Before use, check whether all parts of the equipment are intact and ensure that the power connection is normal. At the same time, select the appropriate screen according to the screening needs and install it in place.

After starting the equipment, pay close attention to its operating status to ensure its smooth operation. If there is any abnormality, stop the machine immediately for inspection and troubleshooting.

During the screening process, the material should be evenly added to avoid material accumulation or clogging of the screen. At the same time, adjust the amplitude and frequency in time according to the actual situation to achieve the best screening effect.

After the screening is completed, the machine should be gradually shut down and the power supply should be disconnected according to the operating procedures. Then carry out necessary cleaning work to keep the equipment tidy and clean.

The 3YK2460 vibrating screen is an efficient, sturdy and easy-to-operate vibrating screening equipment. Its three-layer wire mesh design greatly improves the screening efficiency and is widely used in many industries. When using it, attention should be paid to the maintenance and maintenance of the equipment to ensure its long-term stable operation.