The 500T/H hard rock aggregate production line is a production line used to process and crush hard materials (such as granite, basalt, etc.). Its design capacity is 500 tons per hour.

500T/H hard rock aggregate production line with Hydraulic cone crusher

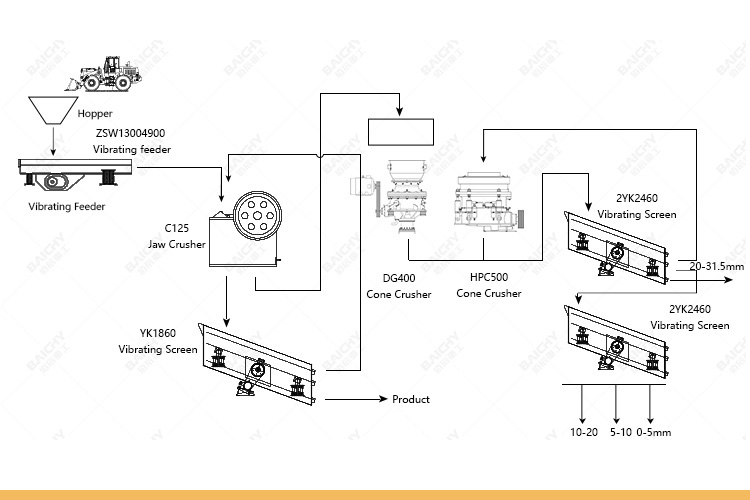

1. Process flow:

● Raw material processing: The large pieces of wool less than 1250mm that have been blasted or excavated and mined are fed to the raw material warehouse through a dump truck.

● Coarse crushing: The raw materials are evenly supplied to the jaw crusher for primary crushing through the rod feeder with a pre-screening function.

● Medium and fine crushing: After being crushed by the jaw crusher, the 100-250mm semi-finished materials are transported to the HPC-500 Hydraulic cone crusher for secondary crushing through a belt conveyor.

● Screening: After secondary crushing, the 6-45mm mixed finished aggregate is transported to the screening workshop through a belt conveyor for classification and screening. The screened materials that do not meet the particle size requirements will be returned to the fine cone crusher for recycling until they meet the requirements.

● Finished product transportation: Qualified finished products that meet customer needs are transported to the finished product silo through a belt conveyor.

2. Equipment configuration:

● The main equipment includes rod feeders, jaw crushers, cone crushers, vibrating screens, etc. These devices are configured according to production needs to ensure efficient operation of the production line.

● Equipment specifications and models may vary by manufacturer and specific needs.

3. Production line features:

● Clean and environmentally friendly: The production line adopts a fully enclosed design, equipped with soundproof factory buildings and sewage treatment systems to effectively control noise pollution and water pollution. At the same time, the spray dust reduction during the wet production process avoids the harm caused by dust.

● Adapting measures to local conditions: The production line is designed to adapt to local conditions, which not only facilitates the use of local materials for the project but also solves the customer's needs for stone production in specific areas.

● Sectional design: The production line is planned to be divided into two parts. The coarse crushing system is located in the raw ore mining area, and the crushing and screening system is located in the park. This design helps improve production efficiency and reduce transportation costs.

Please note that the specific 500T/H hard rock aggregate production line plan may vary depending on customer needs, raw material characteristics, production environment, and other factors. Therefore, in practical applications, it needs to be designed and adjusted according to specific conditions.