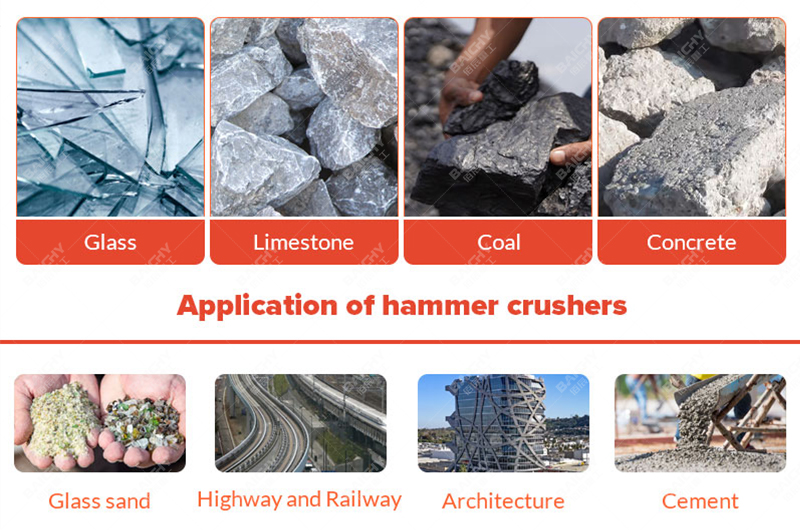

Hammer Crusher is very suitable for crushing coal and is widely used in coal mines, coking plants and other scenarios.

Advantages of Hammer Crusher in Crushing Coal

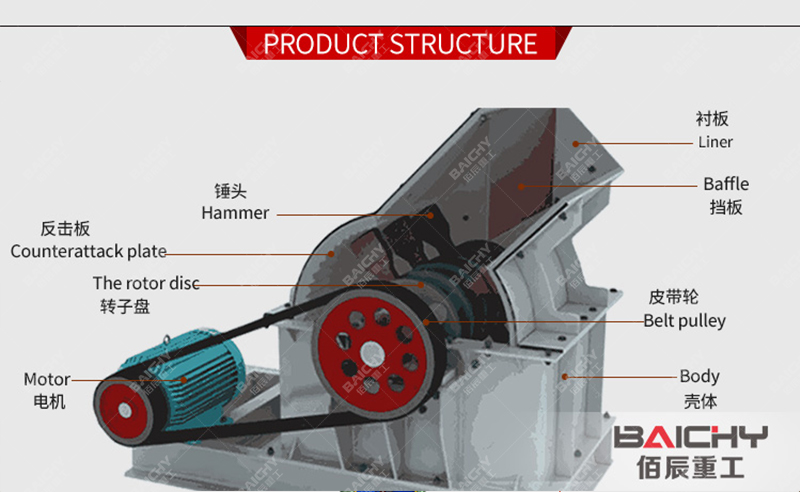

1. Efficient crushing: The high-speed rotating hammer head (usually made of alloy steel) quickly crushes coal blocks through strong impact, which is especially suitable for raw coal with medium and low hardness (the compressive strength of coal is generally between 30-80 MPa).

2. Strong adaptability: It can process raw coal containing a small amount of gangue (rock mixed in coal), but attention should be paid to the hardness of the gangue (if the gangue is too hard, it may accelerate the wear of the hammer head).

3. Low energy consumption: Compared with traditional jaw crushers, hammer crushers have lower energy consumption and high crushing efficiency.

4. Flexible adjustment: By replacing the screen plate or adjusting the arrangement of the hammer heads, the discharge particle size (such as 10-50 mm) can be controlled to meet different process requirements.

Hammer crusher application scenarios

1. Raw coal crushing: initial crushing of large pieces of raw coal in coal mines.

2. Coke crushing: secondary crushing or screening of coke in coking plants.

3. Gangue treatment: crushing and reduction of coal gangue.

4. Supporting equipment: often combined with conveyors, vibrating screens, etc. to form a production line to achieve continuous operation.

Precautions for using hammer crushers

1. Material pretreatment: It is recommended to screen out large pieces of sharp rocks (such as ironware) in advance to prevent damage to the hammer or screen.

2. Humidity control: If the moisture content of the raw coal is too high (>15%), it may cause blockage or adhesion of the hammer. It is necessary to increase the drying process or select an anti-blocking screen plate.

3. Hammer material: Select the hammer material (such as high chromium alloy steel, composite hammer) according to the hardness of the coal to extend the service life.

4. Safety protection:Regularly check the dust seal and overload protection device of the equipment to avoid dust explosion or equipment failure.

Situations where hammer crushing is not recommended

1. Superhard materials: If the coal is mixed with ultra-high hardness rocks (such as granite), it is recommended to use a jaw crusher or impact crusher instead.

2. Ultrafine crushing: When coal powder with a particle size of <5 mm is required, the hammer crushing efficiency is low and can be used with a fine crusher or ball mill.

Hammer crusher is an economical and efficient choice for crushing coal, but it needs to be selected comprehensively based on coal quality, output requirements and budget. If specific model parameters (such as PC0808) are required, it is recommended to provide material characteristics (such as maximum block size, gangue content, etc.) for further analysis.