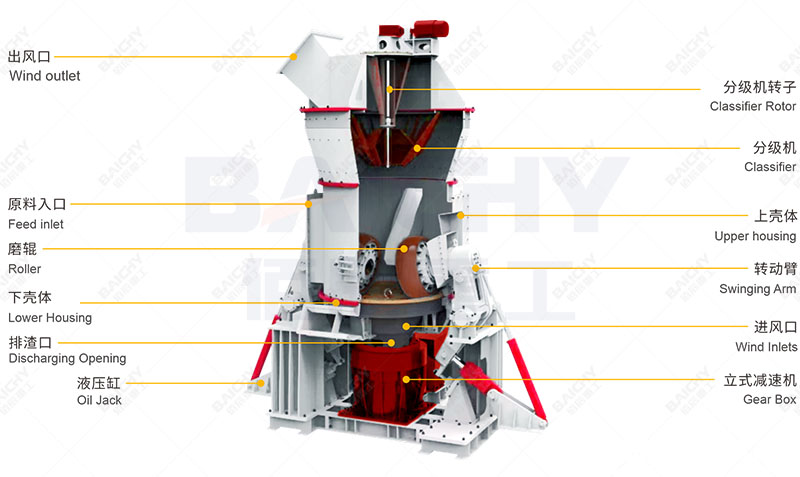

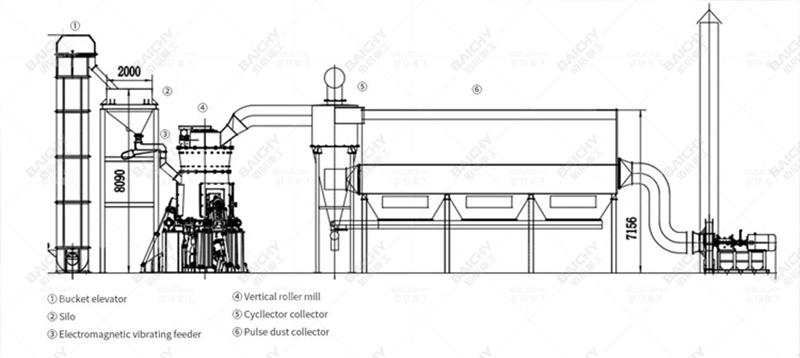

SRM1300 Vertical Roller Mill Equipment Overview

SRM1300 vertical roller mill is a high-efficiency grinding equipment, widely used in large and medium-sized mining, chemical, building materials, metallurgy, refractory materials, pharmaceuticals, cement and other industries. Its processing capacity ranges from 10-35 tons/hour, which can meet the needs of production lines of different scales.

Working principle of SRM1300 vertical roller mill

The working principle of SRM1300 vertical roller mill mainly depends on the interaction between the grinding roller and the grinding disc. The raw material is fed into the center of the rotating grinding disc through the air supply equipment. Under the action of centrifugal force, the material moves to the area around the grinding disc and enters the grinding roller slider. Under the action of roller pressure, the material is crushed by extrusion, grinding, shearing and other actions. At the same time, hot air flows upward from the air ring, dries the suspended material and brings it into the grading system. In the grading system, qualified powder enters the powder collector with the air flow to become a finished product, and unqualified powder returns to the mill for re-grinding.

Advantages of grinding fine raw materials

1. High efficiency: The SRM1300 vertical roller mill adopts high-speed rotating bidirectional pushing action, so that every part of the material can be fully utilized and the grinding efficiency is high.

2. Low energy consumption: The internal structure of the equipment is exquisite, which can effectively control overload and reduce energy consumption. Compared with traditional mills, the SRM1300 vertical roller mill saves 30%-50% energy when producing products of the same fineness grade.

3. Easy operation and maintenance: Modern technology makes the operation of the vertical roller mill simpler and more intuitive. At the same time, most models are equipped with an automatic fault diagnosis system, which simplifies the user's identification and solution process of problems. In addition, regular inspection, cleaning and replacement of durable parts can ensure the good operation of the equipment.

4. Wide adaptability: By adjusting parameters (such as conveyor belt speed and impact force), the SRM1300 vertical roller mill can adapt to materials of different hardness and toughness while ensuring the best output quality. This makes it a great advantage in grinding fine raw materials.

SRM1300 vertical roller mill application field

SRM1300 vertical roller mill is suitable for grinding gypsum, talc, calcite, limestone, marble, barite, dolomite, granite, kaolin, bauxite, red iron oxide and other raw materials. After grinding, these raw materials can be used to manufacture various chemical products, building materials and metallurgical materials.

SRM1300 vertical roller mill has significant advantages and a wide range of applications in grinding fine raw materials. Its high efficiency, low energy consumption, easy operation and maintenance, and wide adaptability make it the preferred grinding equipment in many industries.