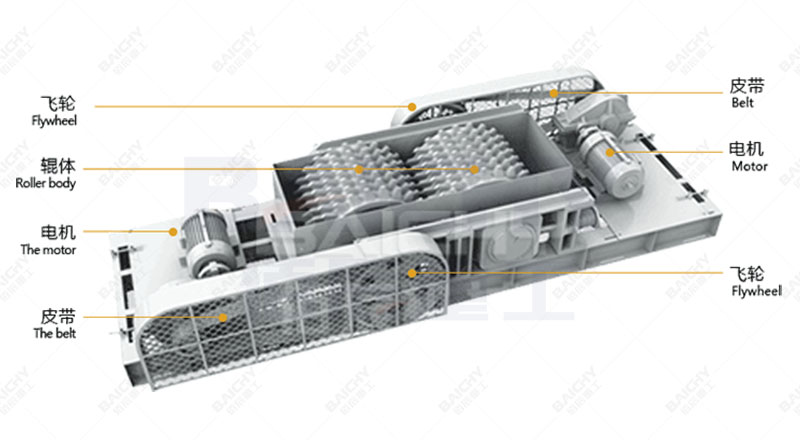

The tooth plate top roller of the double-toothed roller crusher is one of its core working parts, which is mainly responsible for the crushing of materials. The following is a detailed description of the tooth plate top roller and an analysis of common problems:

Function and structure of the tooth plate top roller of the double-toothed roller crusher

Cooperating with the moving roller, the materials are squeezed, sheared and crushed by the opposite rotation of the two rollers.

The tooth plate (toothed liner) directly contacts the material, and its shape and arrangement directly affect the crushing efficiency and the particle size of the output material.

Structural features

• Material: usually high manganese steel (such as ZGMn13), alloy steel or surfacing wear-resistant layer are used to improve wear resistance.

• Tooth design: divided into wolf teeth, rectangular teeth, diamond teeth, etc., selected according to the hardness and particle size requirements of the material.

• Installation method: fixed to the surface of the roller body by bolts or welding, and the tightening status needs to be checked regularly.

Common problems and solutions of double-toothed roller crusher

Tooth plate wears too fast

• Reason: material hardness is too high, tooth plate material does not match, and the pressure between rollers is too large.

Solution:

• Replace the tooth plate with a higher wear-resistant material (such as tungsten carbide surfacing).

• Adjust the roller spacing to avoid overload operation.

• Check whether the material meets the crushing range of the equipment (such as avoiding the entry of metal impurities).

Uneven crushing particle size

• Cause: uneven wear of the tooth plate, mismatched roller speed, and large fluctuations in feed particle size.

Solution:

• Turn over or replace the tooth plate regularly to maintain symmetrical wear.

• Adjust the speed difference between the two rollers to optimize the shearing effect.

• Add a pre-screening device to control the feed size.

Abnormal vibration or noise

• Cause: loose tooth plate, damaged bearing, unbalanced roller body.

Solution:

• Tighten the tooth plate bolts and check whether the welding parts are cracked.

• Replace damaged bearings and ensure good lubrication.

• Stop the machine to check the dynamic balance of the roller body.

Maintenance and maintenance suggestions for double-toothed roller crusher

Daily inspection

• Check the wear of the tooth plate every shift and record the thickness change.

• Clean the foreign matter stuck between the teeth to prevent overload.

Lubrication management

• Regularly add high-temperature grease (such as lithium-based grease) to bearings and gears.

• Avoid bearing burnout due to insufficient lubrication.

Replacement cycle

• Depending on the hardness of the material, the life of the tooth plate is usually 3-12 months.

• Symmetrical tooth plates need to be replaced synchronously to avoid uneven force.

Optimization suggestions for double-toothed roller crusher

• Tooth shape improvement: For highly abrasive materials, a staggered short tooth design is adopted to reduce stress concentration.

• Automatic adjustment: Add a hydraulic system to adjust the roller spacing in real time to adapt to different working conditions.

• Pre-protection measures: Install an iron remover and a metal detector at the feed inlet to extend the life of the tooth plate.

Safety operation tips for double-toothed roller crusher

• Be sure to cut off the power supply and lock it during maintenance.

• Avoid cleaning materials during operation to prevent mechanical damage.

If you need to further solve specific problems (such as selection, fault diagnosis), please provide more details (such as material characteristics, equipment model, fault phenomenon) for targeted analysis!