The sand and

gravel dewatering screen is a device for washing, dehydrating and grading sand, and is mainly used in scenes such as sand washing in sand and gravel plants.

Definition and function of sand and gravel dewatering screen

Sand and gravel dewatering screen, also known as a sand and gravel dewatering machine or sand washing and dewatering screen, is a device that uses the principle of vibration to dehydrate wet sand.

Sand and gravel dewatering screens are mainly used to effectively remove moisture from wet sand, improve the dryness and cleanliness of sand, and achieve sand grading at the same time.

Working principle of sand and gravel dewatering screen

The sand and gravel dewatering screen uses a double vibration motor or flange exciter as the power source and drives two vibrators to run synchronously in reverse through a coupling. The centrifugal force generated by this operation mode is superimposed to form an exciting force along the vibration direction so that the screen box moves back and forth in a straight line. Under the action of vibration force and gravity, the material on the screen surface continuously jumps forward, and the material smaller than the screen hole penetrates the screen surface and is discharged, thereby achieving the purpose of dehydration, desludging, and grading.

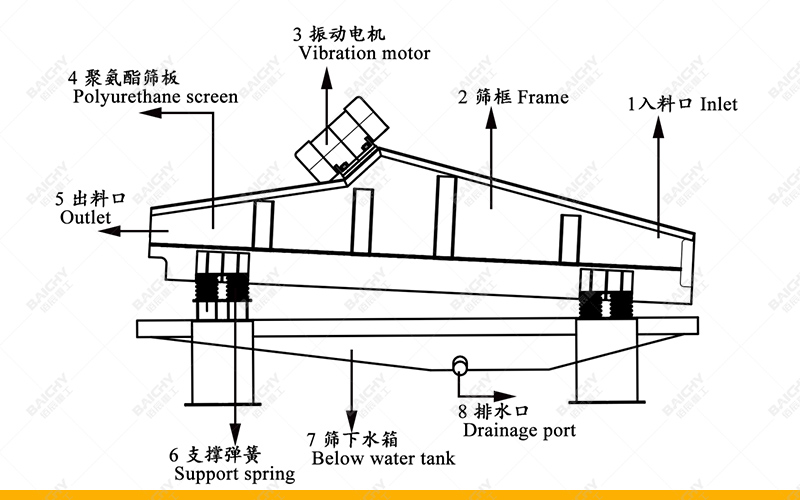

Structural composition of sand and gravel dewatering screen

The sand and gravel dewatering screen is mainly composed of a screen, vibrator, adjustment device, and support base:

• Screen: It is the core component of the dewatering screen. It is made of high-strength and wear-resistant materials and can withstand the high-speed movement and friction of sand and gravel.

• Vibrator: It is the power source of the dewatering screen. The vibration waves generated by high-speed vibration make the sand and gravel form a uniform flow layer on the screen, which is conducive to the rapid separation of water.

• Adjustment device: The vibration frequency and amplitude of the vibrator can be adjusted according to parameters such as the particle size and moisture content of the sand and gravel to achieve the best dewatering effect.

• Support base: It is the supporting structure of the dewatering screen. It is made of high-strength and stable materials to ensure the stable operation of the dewatering screen.

Characteristics and advantages of sand and gravel dewatering screen

1. Good dewatering effect: It can effectively remove moisture from the sand and improve the dryness and cleanliness of the sand.

2. Good grading effect: The grading treatment of sand can be achieved through the screening effect of the screen.

3. Reasonable structure: reasonable design, stable and reliable operation, and easy maintenance.

4. Wide range of applications: widely used in sand and gravel plants, sand mining sites, mines, and other scenes.

Application and selection of sand and gravel dewatering screen

Sand and gravel dewatering screen is widely used in scenes such as sand washing in sand and gravel plants. When selecting, it is necessary to consider factors such as equipment processing capacity, screening accuracy, dewatering effect and operating cost according to actual needs. At the same time, it is also necessary to consider the stability and durability of the equipment to ensure long-term stable operation.

Use and maintenance of sand and gravel dewatering screen

1. Preparation before use: Check whether all parts of the equipment are intact, and ensure that the vibrator, screen, etc. are not damaged; check whether the power supply and motor are normal; check whether the adjustment device is flexible and reliable.

2. Precautions for use: Avoid overload operation; pay attention to the vibration and noise of the equipment; regularly check whether the screen is blocked or worn; regularly clean up the debris inside and around the equipment.

3. Maintenance: Regularly lubricate all parts of the equipment; regularly replace worn screens and vibrators; regularly clean and inspect the equipment; promptly detect and handle equipment failures.

The sand and gravel dewatering screen is an important sand and gravel processing equipment, which plays an important role in scenes such as sand and gravel plants. By reasonably selecting and using the sand and gravel dewatering screen, the quality and output of sand can be improved, production costs can be reduced, and economic benefits can be improved.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.