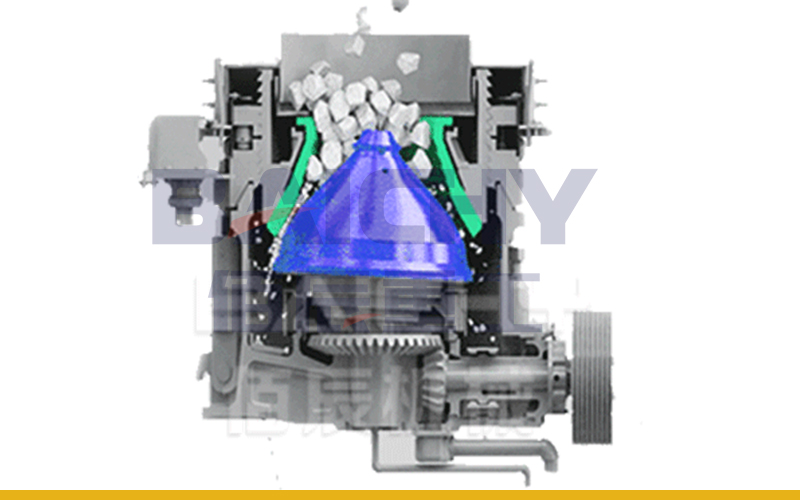

The principle of cone crusher can be clearly summarized into the following key steps:

Motor drive: The working principle of the cone crusher first depends on the drive of the motor. The rotation of the motor is transmitted to the transmission shaft through a pulley or coupling, thereby driving the cone to move.

Conical body swinging motion: Under the force of the eccentric sleeve, the cone moves around a fixed point. This motion makes the crushing wall of the cone crusher approach and leaves the surface of the whitening wall fixed on the adjustment sleeve.

Material crushing: Material enters the crushing cavity of the cone from above and is crushed by impact, extrusion, and bending under the action of cone rotation and eccentricity. Material is compressed, bent, and sheared, so as to achieve the crushing effect.

Ore discharge and insurance mechanism: The crushed material is discharged from the discharge port. When unbreakable foreign matter passes through the crushing cavity or the machine is overloaded for some reason, the spring insurance system realizes insurance, the discharge port is enlarged, and the foreign matter is discharged from the crushing cavity. If foreign matter is stuck in the discharge port, the cavity cleaning system can be used to make the discharge port continue to enlarge to remove foreign matter. Under the action of the spring, the discharge port automatically resets and the machine resumes normal operation.

Finished product particle control: The size of the finished product particles can be controlled by adjusting the gap between the cone and the crushing wall to meet different needs.

In summary, the cone crusher drives the cone to swing through the motor, so that the material is crushed by impact, extrusion and bending in the crushing chamber. At the same time, the equipment is equipped with a discharge and insurance mechanism to ensure that foreign matter can be safely removed and normal operation can be resumed under abnormal circumstances. In addition, the size of the finished product particles can be controlled by adjusting the gap between the cone and the crushing wall.