The dolomite crushing production line is a complete production process used to crush dolomite raw materials into required particle sizes. This production line usually consists of multiple pieces of equipment and steps.

The following is a basic overview of a typical dolomite crushing production line:

1. Coarse crushing: Dolomite raw materials first pass through coarse crushing equipment, such as jaw crushers. The jaw crusher crushes materials by simulating the movement of an animal's jaws, initially breaking them into smaller pieces.

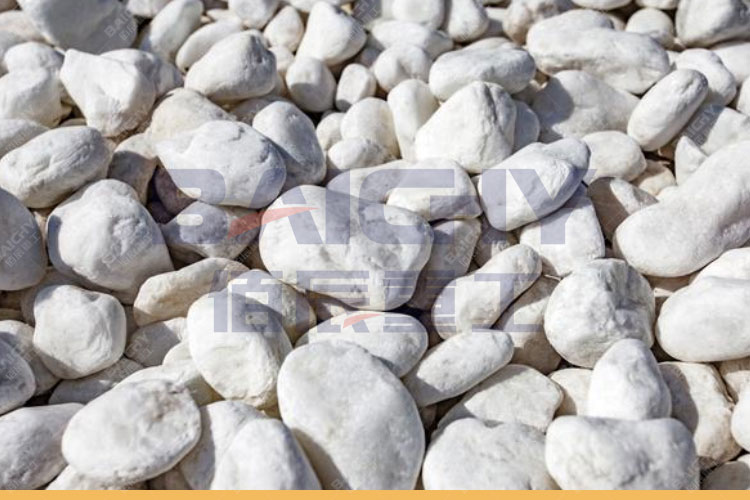

2. Medium and fine crushing: After coarse crushing, the dolomite materials enter the medium and fine crushing equipment, such as cone crusher or impact crusher. These devices further break the material into smaller particles.

3. Screening: The crushed dolomite materials are screened through screening equipment to separate materials of different particle sizes. The screening equipment can adjust the screen aperture according to production needs to obtain the required aggregate particle size.

4. Conveying: The screened dolomite aggregate is transported to designated storage areas or further processing equipment through conveying equipment, such as belt conveyors or bucket elevators.

5. Dust removal and environmental protection measures: Throughout the production process, necessary dust removal and environmental protection measures should be taken, such as installing dust removal equipment, sprinkling water to reduce dust, etc., to reduce dust pollution and noise pollution.

6. Control system: Dolomite crushing production lines are usually equipped with advanced control systems for monitoring and controlling the entire production process. The control system can monitor the equipment's operating status, material flow, particle size distribution, and other parameters in real-time, and make adjustments and optimizations as needed.

It should be noted that the specific configuration and process of the dolomite crushing production line may vary depending on production needs, raw material characteristics, equipment selection, and other factors. Therefore, in practical applications, it needs to be designed and adjusted according to specific conditions.

In addition, with the continuous development of technology, dolomite-crushing production lines are also constantly innovating and improving. For example, some advanced production lines adopt automation and intelligent technologies to improve production efficiency and product quality and reduce production costs and energy consumption. At the same time, environmental protection and sustainable development have also become important considerations in the current design of dolomite-crushing production lines.