The output of gold mine investment is gold, which is loved by consumers all over the world and well-known by investors. Against the backdrop of collective gold reserves increase in China, Russia and other countries, global gold consumption and investment demand are growing, which provides a sales guarantee for gold mine output. Whether it is investing in gold jewelry or investment products, there is huge market potential.

The

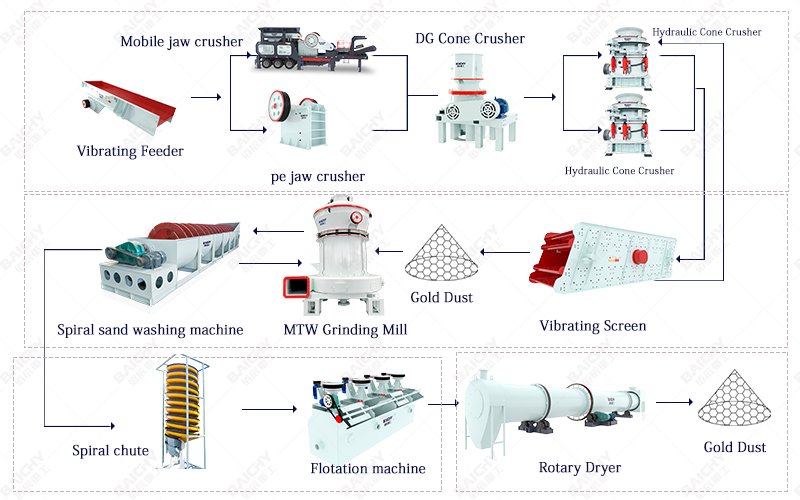

gold ore processing and production process mainly includes three processes: crushing, grinding and beneficiation:

In the crushing process, three-stage closed-circuit crushing is a modern method suitable for gold ore crushing, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding efficiency;

In the grinding process, two-stage one-closed grinding can make the gold ore more fully ground;

In the beneficiation process, due to the different types and properties of gold ores, the beneficiation methods used are also different, but gravity separation, flotation, mercury mixing, cyanidation and today's resin slurry method, carbon slurry adsorption method, heap leaching method are generally used for gold extraction. For some types of ores, a combined gold extraction process is often used.

The first stage: crushing and screening - three-stage closed-circuit crushing

The large pieces of gold ore are evenly fed into the

jaw crusher or the

mobile crushing plant for coarse crushing by the vibrating feeder through the silo; the coarsely crushed gold ore is screened by the vibrating screen and sent to the single-cylinder

hydraulic cone crusher by the belt conveyor for medium crushing; the gold ore material after medium crushing is sent to the multi-cylinder hydraulic cone crusher for fine crushing;

The second stage: grinding

The 0-12 mm gold powder screened by the

vibrating screen is evenly fed into the grinding machine for grinding, and screened by the spiral classifier, and those that do not meet the requirements are sent to the grinding machine for further grinding;

The third stage: ore dressing

In the ore dressing process, due to the different types and properties of gold ores, the ore dressing methods used are also different, but gravity separation, flotation, mercury mixing, cyanidation, and the current resin slurry method, carbon slurry adsorption method, heap leaching method are generally used for gold extraction. For some types of ores, a combined gold extraction process is often used.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.