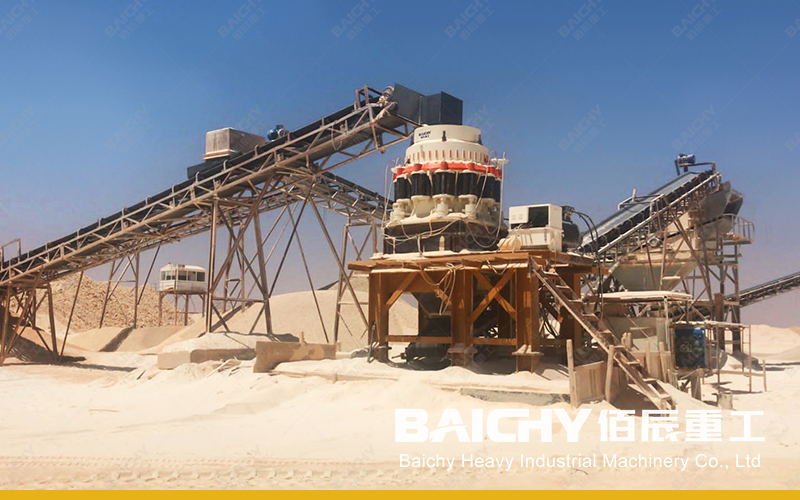

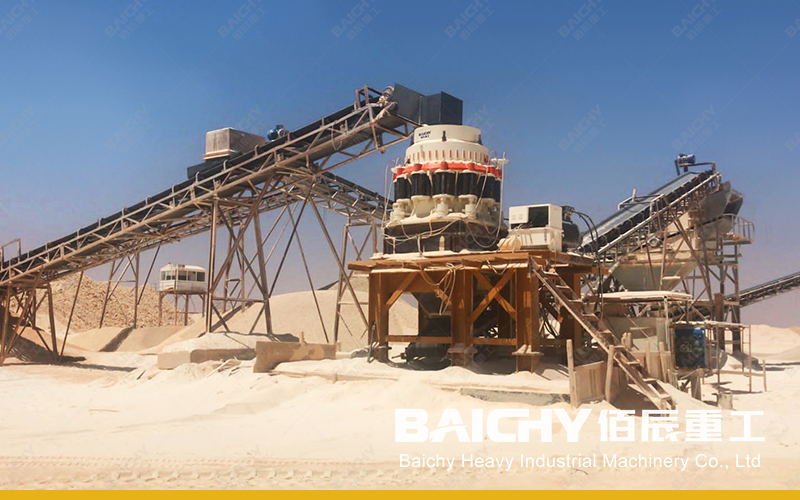

For 80-100 t/h jaw and cone crushing stations, equipped with crushing and screening systems is a comprehensive project designed to efficiently process large amounts of materials such as ore, rock, construction waste, etc.

Jaw crusher

• Function: As a primary crushing equipment, the jaw crusher is mainly used to crush large pieces of material into smaller particles for subsequent processing.

• Features: simple structure, reliable operation, large crushing ratio, suitable for materials of various hardness.

• Selection: Select the appropriate jaw crusher model according to the processing capacity (80-100 t/h) and material characteristics (such as hardness, moisture, particle size distribution, etc.).

Cone crusher

• Function: As secondary or tertiary crushing equipment, the cone crusher further refines the material to achieve the required particle size requirements.

• Features: high crushing efficiency, low energy consumption, uniform product particle size, suitable for medium and fine crushing operations.

• Selection: Also select the appropriate cone crusher model according to the processing capacity and material characteristics.

Screening system

• Function: The screening system is used to classify the crushed materials according to the particle size to meet different usage requirements.

• Equipment: Common screening equipment includes vibrating screens, circular vibrating screens, etc. These devices make the materials jump and roll on the screen surface through vibration, thereby achieving particle size classification.

• Configuration: According to the processing capacity of the crushing station and the product particle size requirements, the corresponding number and specifications of screening equipment are configured. Usually, the screening system is used in series with the crusher to form a closed loop to improve the crushing efficiency and product quality.

Equipping the 80-100 t/h jaw and cone crushing station with a crushing and screening system is a complex project that requires comprehensive consideration of multiple factors. By rationally configuring equipment, optimizing process flow, and strengthening equipment maintenance and management, the efficient and stable operation of the crushing station can be ensured.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.