Choosing the right pebble crusher for your site requires considering several factors. Here are some key considerations and suggestions:

Pebble characteristics:

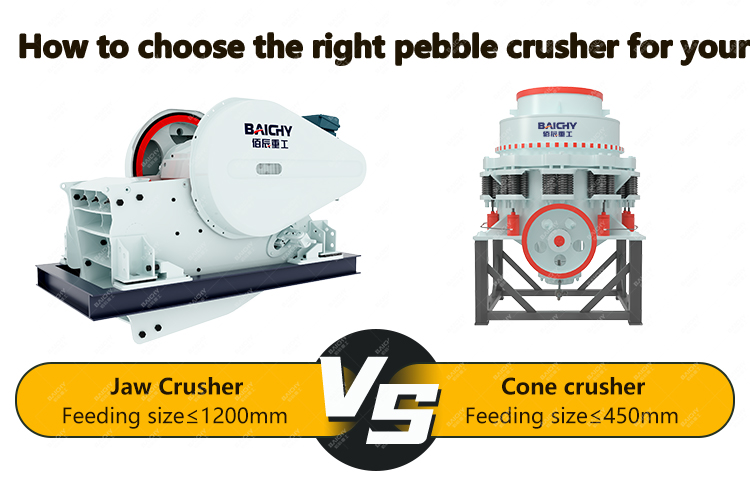

Hardness and size: The hardness and size of the pebbles are key factors in choosing a crusher. For pebbles with higher hardness, a crusher with strong wear resistance is generally selected, such as a jaw crusher. There are also corresponding crusher options for pebbles of different sizes. For example, the jaw crusher is suitable for small and medium-sized pebbles, while the hammer crusher is suitable for larger-sized pebbles.

Purpose: The end use of the pebbles will also influence crusher selection. Different uses of pebbles may require different crusher models and discharge particle sizes.

Crusher types and features:

Jaw crusher: It has the characteristics of strong wear resistance, high-quality accessories materials (such as high-strength steel), high swing frequency, and optimized shape of the crushing cavity. It is suitable for coarse crushing of various ores, and the finished product has uniform particle size, which can meet the high-standard material requirements in the construction field.

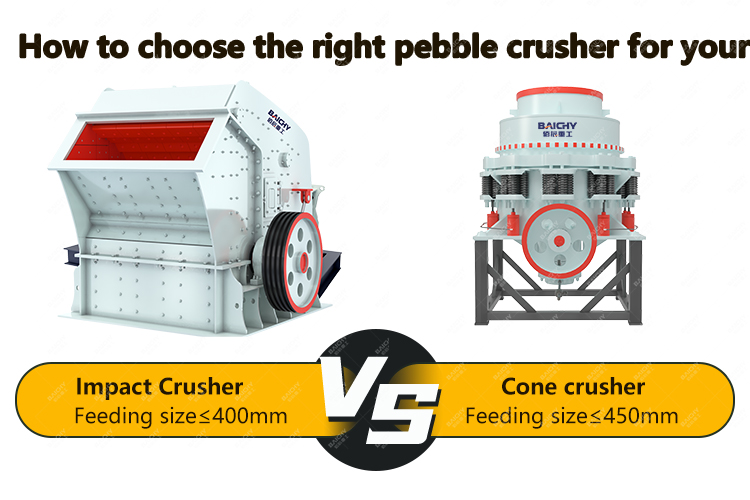

Cone crusher: used for medium or fine crushing of pebbles. It has the advantages of layered crushing, a large crushing ratio, and the good shape of the finished particles. In addition, its overload protection device protects the machine from foreign iron pieces, and the cavity can be changed at will to meet the needs of different product granularities.

Impact crusher: suitable for finely crushing pebbles to make sand, and can crush pebbles into a smaller particle size range. Its deep cavity impeller design increases the throughput of pebbles per unit of time.

Production capacity requirements: Select a crusher with appropriate processing capacity based on the actual needs of the site. Different models of crushers have different processing capacities, ranging from a few tons to thousands of tons per hour.

Cost considerations: The price of a pebble crusher is affected by many factors, including region, sales model, and transportation. When choosing a crusher, in addition to considering its performance and applicability, you also need to consider the budget comprehensively.

After-sales service and maintenance: Choose a crusher brand or supplier with good after-sales service and maintenance support to ensure stable operation and timely maintenance of the equipment.

Choosing the right pebble crusher for the site requires comprehensive consideration of pebble characteristics, crusher type and characteristics, production capacity requirements, cost, and after-sales service and maintenance. It is recommended to communicate with a professional crusher supplier or manufacturer to make a customized selection based on the actual site conditions and needs.