Raw materials: weathered rock

Project address: Kazakhstan

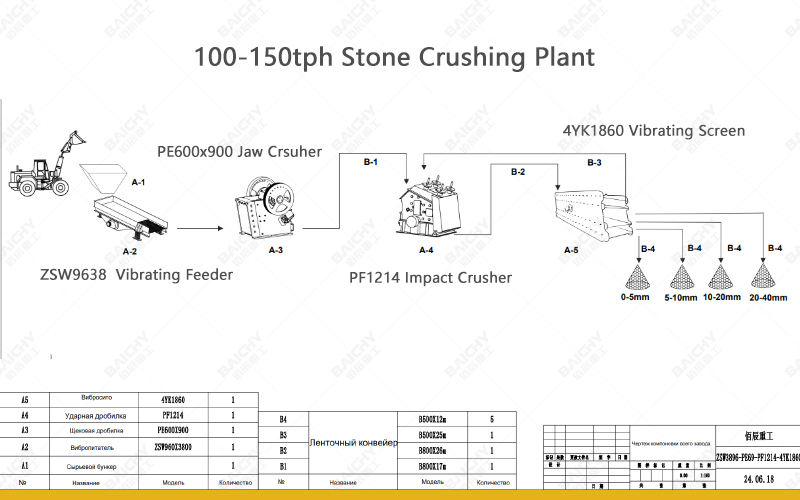

Capacity: 100-150tph

Main equipment: ZSW9638 feeder, pe600x900 jaw crusher, PF1214 impact crusher, 4YK1860 vibrating screen;

What is weathered rock?

Weathered rock refers to the phenomenon that rocks are broken, loosened and their mineral composition changes under the action of solar radiation, atmosphere, water and organisms. This action is called weathering.

The physical and mechanical properties of weathered rock decrease with the increase of weathering degree, such as strength, hardness, density and other indicators will decrease; weathered rock has strong permeability and is easy to become a channel and storage space for groundwater; weathered rock has poor stability and is easy to deform and damage under the action of external loads or natural factors.

100-150tph weathered

rock crushing production line is a crushing and processing system specially used for processing weathered rock. It is designed to efficiently and stably crush weathered rock into aggregate or sand of the required particle size. The production line is usually composed of feeder, crusher, screener, conveyor and other equipment, which can realize automatic continuous operation.

Weathered rock crusher: It is the core equipment of the production line, which is used to crush weathered rock into smaller particles. According to the hardness and particle size requirements of weathered rock, different types of crushers can be selected, such as jaw crusher, cone crusher, impact crusher, etc.

1.

Jaw crusher: It is usually used in the coarse crushing stage and can handle large pieces of weathered rock.

2.

Impact crusher: It can also be used in the medium and fine crushing stage, especially suitable for processing soft and medium hard weathered rock.

The weathered rock raw material is first fed into the jaw crusher through the feeder for coarse crushing, and the coarsely crushed material is then fed into the impact crusher through the conveyor for medium and fine crushing. The medium and fine crushed materials are screened by a screening machine to obtain products of different particle sizes. The screened products can be further processed or sold directly as finished products as needed.

Features of weathered rock crushing production line

• High efficiency: The production line adopts an automated continuous operation mode, which can greatly improve production efficiency.

• Stability: Reasonable equipment selection and scientific process flow can ensure the stable operation of the production line.

• Flexibility: The type and parameters of the crusher can be adjusted according to the hardness and particle size requirements of the weathered rock to meet different production needs.

• Environmental protection: The production line pays attention to environmental protection requirements during design and operation to reduce dust and noise pollution.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.