Recently, many clients have asked me this way:

"Hello, what is the price of the PE600x900 jaw crusher? Is the motor included in this package, if not, can you include one in the order? How much does it cost in total?"

The price of the crusher is a question that everyone is more concerned about, and what accessories does this crusher include?

We did market research and found that the price of pe600x900 is between 13,200$-36,000$. At this time, the customer asked again, why is there such a big difference in price for the same model?

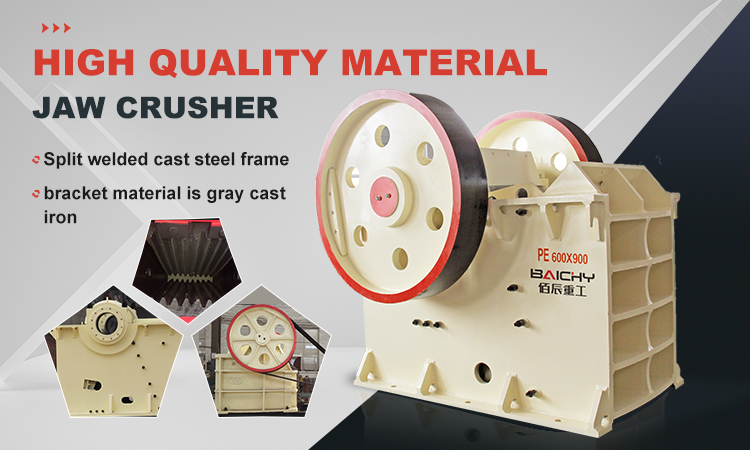

I will first let you know about the materials I only make in Jaw Crusher

High manganese steel

High-manganese steel is the traditional material of jaw crusher. It has good toughness and good bending hardening ability. However, due to the incorrect structure of the current jaw crusher, the opening angle between the movable and fixed jaws is too large, which is easy to cause. The high manganese steel is deformed and hardened due to the sliding of the abrasive, the Mohs hardness of the surface of the jaw plate is low, the short-cut cutting amount of the abrasive is large, and the jaw plate wears quickly. Therefore, to improve the wear resistance of the high manganese steel jaw plate, It is to modify the structure of the jaw crusher, reduce the sliding of the abrasive on the appearance of the jaw plate as much as possible, and allow the potential of the high-manganese steel to be deformed and hardened; the second is to modify the high-manganese steel, but the modification treatment of the high-manganese steel, However, it greatly damages its toughness. In some working conditions, the modified high-manganese steel jaw plate is prone to early fracture and is ineffective.

Medium manganese steel

High manganese steel has low initial Mohs hardness, low yield stress performance, small crushing and hardening in non-strong impact conditions, and easy rheology and cutting. Steel and medium manganese steel have achieved good results in practical applications. For example, when crushing silica, the use time of the jaw plate of high manganese steel is increased by more than 20%, and the capital is equivalent to that of a high manganese steel jaw plate. Therefore, for small and medium output For jaw crushers, medium manganese steel is a kind of jaw plate material worth promoting.

High chromium cast iron and high manganese steel composite

Although high-chromium cast iron is an excellent wear-resistant material for the jaw crusher, due to its poor toughness (usually Ak is 5-8J/cm2), it will be directly broken or bent a few times when the stone is impacted or squeezed. In recent years, high-chromium cast iron is selected to be cast or bonded to the high-manganese steel jaw plate, and the composite jaw plate is combined to make the best use of high-chromium cast iron. It is possible to exert the high wear resistance of high chromium cast iron and the high toughness of high manganese steel so that the service life of the jaw plate can be significantly improved. This is a way to improve the service life of the jaw plate, but the production plan is more complicated and the workmanship requirements are relatively high. Therefore, the production is difficult, which limits the application of this type of composite jaws.

Low alloy cast steel

Medium-carbon low-alloy cast steel is currently a commonly used wear-resistant material, mainly due to its improved Mohs hardness (HRC not less than 45) and suitable toughness (Ak not less than 15J/m2), which can resist The cutting effect of the stone and the fatigue spalling caused by the repeated extrusion of the stone show good wear resistance. The same-steel medium-carbon low-alloy cast steel can also be adjusted by factors and heat treatment to improve the Mohs hardness and toughness. Transform in a larger area to meet the requirements of different working conditions.

The materials of the above four types of jaw crushers are different, and the scope of application is also different. When choosing, according to the requirements of their own conditions of use, choose satisfactory materials to meet better use.

Of course, the price of the material that cannot be used will also be different, and the price in the natural market is also uneven.

Please contact Us: 0086 15093222637