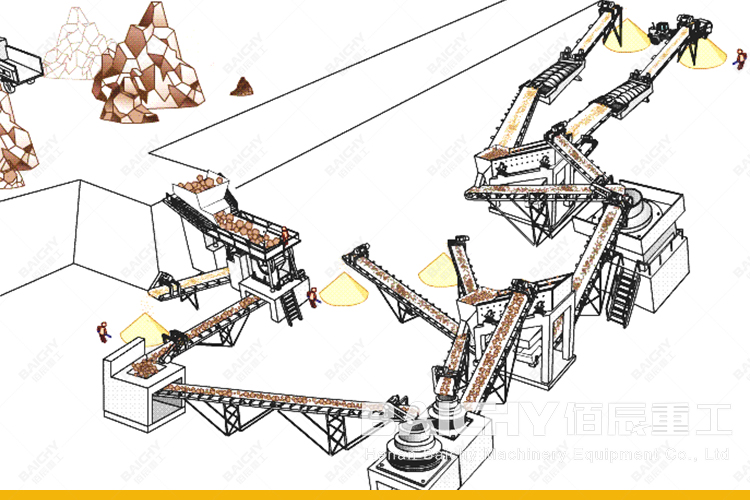

The working process of the stone crushing plant is systematic. From the input of raw materials to the output of finished products, all links are closely connected to ensure the smooth progress of the crushing work. The following is the basic working principle of stone crushing station:

First, raw stone is sent to the crushing station through transportation equipment such as trucks or conveyor belts. Before crushing, the raw materials need to be pretreated to remove dust and impurities to ensure the smooth operation of the crushing system.

Then, the raw stone enters the primary crushing stage. This stage usually uses a jaw crusher or impact crusher for coarse crushing. These crushers break rough stones from larger pieces into smaller particles through squeezing, chopping, and crushing of the movable and fixed jaws.

Then, the primary crushed stone enters the intermediate crushing stage through the conveying device. This stage may use a cone crusher or other type of crusher for further crushing and refining to bring the stone to a smaller particle size.

In the crushing process, the parts and structures inside the crusher play a key role. High-quality materials and precise processing ensure the crusher's wear resistance and efficiency. At the same time, the design of the crusher also focuses on energy saving and environmental protection, reducing energy consumption and noise, and improving production efficiency.

After the crushing is completed, the stone enters the screening system. The screening equipment separates the stone into different specifications and sizes according to the needs. The graded finished stones are separated, while the oversized stones are sent back to the crushing system for re-crushing, forming a closed circuit for multiple cycles to ensure that all stones can reach the required particle size.

Finally, the screened finished stone is transported to the storage or loading area through conveyor belts and other conveying equipment. These finished stones can be combined and graded according to customer needs to meet the needs of different projects and applications.

During the entire work process, the stone crushing station requires efficient equipment coordination and strict operational control to ensure the quality and efficiency of the finished stone produced. At the same time, to protect the environment, the crushing station is also equipped with auxiliary facilities such as dust removal equipment to reduce the impact of dust and noise on the surrounding environment.

In short, the stone crushing station processes raw stone into finished stone that meets the requirements through systematic crushing, screening, and transportation processes, providing high-quality raw materials for construction, roads, mining, and other fields.