Applicable materials: cement, limestone, quicklime, lime clinker, etc.

Production capacity: 200 tons/day-8000 tons/day

Baichy cement production line

1. Low failure rate;

2. High yield, low consumption, and low pollution;

3. The production line has a long service life;

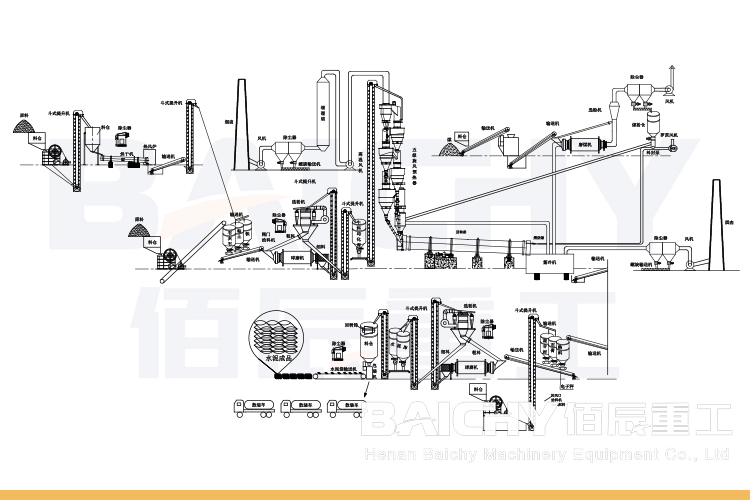

Cement production line process flow

Limestone is more commonly used in the cement preparation process, but the mined limestone generally has larger particle sizes and needs to be crushed. Generally speaking, processing limestone into cement requires the preparation and homogenization of raw materials, the preparation of pulverized coal, the calcination of clinker, and the grinding of cement. stage.

1. Preparation and homogenization of raw meal: natural limestone, clay, and exotic raw materials are crushed by a jaw crusher and mixed in a certain proportion, and then ground by a ball mill to prepare raw meal with appropriate composition and uniform quality;

2. Pulverized coal preparation: The coal required for calcining cement raw materials must be prepared into pulverized coal to provide the particle size required for pulverized coal combustion to facilitate full combustion and obtain sufficient combustion reaction capacity. In this process, pulverized coal can be directly added, and equipment such as jaw crushers and ball mills will be used for processing.

3. Clinker calcination: Put the lime raw material in the rotary kiln and calcine it until it is partially melted to obtain lime clinker.

4. Cement grinding: that is, adding an appropriate amount of gypsum, mixed materials, or additives to the clinker to grind it into cement, and then package it for shipment.

Advantages of the cement production line

1. Low failure rate: Baichy Machinery has 20 years of quality assurance, and the cement plant equipment produced is of excellent quality, which can ensure the normal operation of the entire production line and has a low failure rate;

2. High output, low consumption, and little pollution: Baichen Heavy Industry’s cement plant equipment is obtained through long-term research and practice, so the entire cement production line has excellent performance, fast production speed, low energy consumption, and little pollution during the production process;

3. Long life of the production line: Because each piece of equipment in the cement production line is of good quality and has excellent performance, the wear and tear and failure rate during the production process are low, which also makes the equipment have a long service life;

4. Less manpower investment: The entire cement production line uses integrated automation equipment, so less manpower is required during the operation of the production line, which can reduce later production investment costs for the enterprise.

Production profit analysis

1. Reduce energy consumption: The cement production line equipment configured by Baichy Machinery has a production capacity that can undertake complete dry process cement production with a daily output of 1,000t/d-10,000t/d. The power consumption rate can be reduced by 20%-30%. It directly reduces production costs, wins profits for customers, and improves the overall benefits of the enterprise. In addition, a reasonable selection of production processes is of great significance in reducing energy consumption.

2. Increase output: The entire cement production line operates smoothly and has a solid structure, which not only reduces maintenance costs but also provides considerable production benefits. According to statistics, in the production process, 1 ton of Portland cement needs to grind at least 3 tons of materials, and the power required accounts for more than 60% of the power of the entire plant, of which raw material grinding accounts for 30%, and cement grinding accounts for about 40%. %, it can be seen that the production efficiency is better.