Cement vertical roller mills and ball mills are both commonly used equipment for grinding cement, and each has some advantages and characteristics. Therefore, determining which one is better requires evaluation based on specific application scenarios and needs.

Vertical roller mills excel in several aspects. First of all, its grinding efficiency is high and its power consumption is 20% to 35% lower than that of a ball mill, which helps reduce production costs. Secondly, the vertical roller mill can perform drying operations and can dry materials with a moisture content of 12% to 20%, thereby saving investment in the raw material drying system. In addition, the particle size of the materials fed into the grinding machine is large, and the maximum feeding particle size can reach about 4% to 5% of the diameter of the grinding roller, generally 40 to 100 mm, which helps reduce the workload of material pretreatment. The vertical roller mill also has the advantages of uniform particle gradation, avoidance of over-grinding, low noise, small wear, and high utilization rate. Its structure is simple and easy to maintain, so it is widely used in building materials, metallurgy, and other fields.

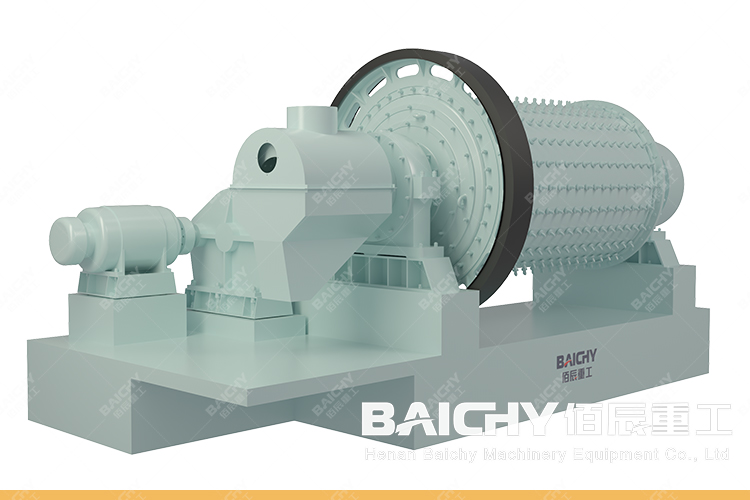

However, ball mills also have their unique advantages. First of all, the ball mill has high energy saving and environmental protection. Secondly, the particle size of the ground material can be adjusted in a wide range, and the particle size distribution is relatively uniform.

All things considered, if energy consumption, drying capacity, and ease of maintenance are of concern, a vertical roller mill may be more suitable. If you pay more attention to the adjustable range of particle size and energy saving and environmental protection, a ball mill may be more suitable.

The final choice should be based on specific application scenarios, material characteristics, production needs, and cost estimates. In actual operation, it is recommended to consult a professional equipment supplier or engineer to obtain more detailed technical support and suggestions.