Crushing 35 cm stone into 1 mm powder requires a combination of multi-stage crushing and grinding equipment. The equipment recommended by Baichy Heavy Industry is sufficient to complete it. Please read for more details. If necessary, you can contact our official customer and our staff will provide more detailed answers.

Equipment selection and process

1. Coarse crushing stage (35 cm → 10-20 cm)

- Equipment: jaw crusher

- As a primary crushing equipment, it is suitable for coarse crushing of large stones, and can crush 35 cm stones to a particle size of 10-20 cm.

- Features: simple structure, strong crushing force, suitable for high hardness ores (such as granite, basalt).

2. Medium crushing stage (10-20 cm → 1-5 cm)

- Equipment: impact crusher or cone crusher

- Impact crusher: uses impact energy to crush materials, suitable for medium hardness stones (such as limestone, sandstone), and the output particle size is more uniform.

- Cone crusher: crushes high-hardness materials through extrusion and bending, suitable for high-yield needs.

3. Fine crushing stage (1-5 cm → 1-5 mm)

- Equipment: hammer crusher or roller crusher

- Hammer crusher: crushes materials through high-speed rotating hammers, and can be formed into smaller particles at one time, suitable for soft to medium-hard materials.

- Roller crusher: uses two rollers to squeeze and crush, and the output particle size can be adjusted to 1-5 mm, suitable for fine crushing and sand making.

4. Grinding stage (1-5 mm → 1 mm powder)

- Equipment: Raymond mill (R-type pendulum mill) or ball mill

- Raymond mill: grinds materials through the rolling action of grinding rollers and grinding rings, and the fineness can reach 80-325 mesh (0.18-0.045 mm). The parameters need to be adjusted to the target particle size (1 mm is about 18 mesh).

- Ball mill: Ultra-fine grinding is achieved through the collision and grinding of steel balls and materials, which is suitable for high-precision requirements.

Key considerations

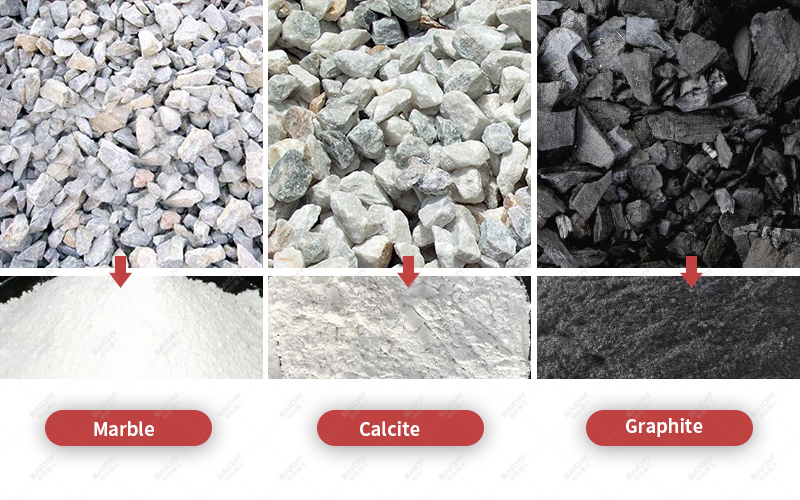

1. Material characteristics

- The hardness of the stone (e.g., granite has high hardness, so a cone crusher is required) directly affects the equipment selection.

- If it contains moisture or impurities, it needs to be pre-screened or dried to avoid clogging the equipment.

2. Equipment linkage and efficiency

- It is recommended to use an automated production line with a vibrating feeder, belt conveyor and screening equipment to improve efficiency.

3. Manufacturer and service

- Choose a manufacturer that provides pre-sales solution design, installation and commissioning, and after-sales support (such as Baichy Heavy Industry) to ensure stable operation of the equipment.

Recommended equipment combination example

1. High-hardness stone: jaw crusher → cone crusher → roller crusher → Raymond mill.

2. Medium-hardness stone: jaw crusher → impact crusher → hammer crusher → ball mill.

Cost and production suggestions

- Budget range: A small production line costs about 100,000-500,000 yuan (depending on the equipment model and output).

- Energy-saving design: Choose equipment with hydraulic adjustment and self-lubricating system to reduce energy consumption and maintenance costs.

- Environmental protection requirements: Use a fully enclosed design to reduce dust pollution.

Welcome to visit! Baichy Heavy Industry welcomes you!