Coke processing projects usually involve the entire process from raw material pretreatment to finished product storage, and the required equipment needs to be configured according to specific process requirements. The following are the core equipment for coke processing and their functions, and are analyzed in combination with Baichen Heavy Industry's product capabilities:

List of main equipment and functions for coke processing projects

1. Jaw crusher: used for coke coking (primary crushing), processing large pieces of raw materials, and strong impact resistance.

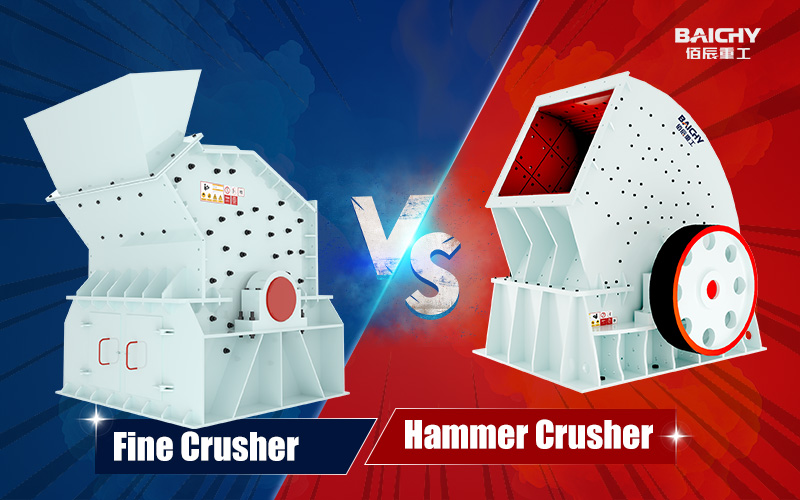

2. Cone crusher/impact crusher: used for medium and fine crushing, controlling the particle size of the finished product (such as 30-80mm for metallurgical coke).

The wear-resistant design of Baichen Heavy Industry's jaw crusher and cone crusher can cope with the high hardness of coke, but it should be noted that coke is relatively brittle, and the crushing cavity needs to be optimized to reduce over-crushing.

3. Vibrating screen (multi-layer screen): Separate coke of different particle sizes, such as grading into metallurgical coke, coke diced, coke powder, etc.

4. Drum screen: suitable for wet screening or high dust environment. Its high-frequency vibrating screen can improve screening efficiency and needs to be equipped with a dust-proof seal design.

5. Belt conveyor: Horizontally or inclined coke conveyor, wear-resistant and anti-deviation belts are required.

6. Bucket elevator: Vertically convey coke powder or small particles.

Baichy Capabilities: Can provide customized conveying systems with integrated dust covers and sweepers.

7. Vibrating feeder: Evenly feeds to crusher or screener to avoid blockage.

8. Plate feeder: Handles large, high-impact raw materials.

9. Bag dust collector: Collects dust from crushing and screening to meet environmental emission standards.

10. Spray system: Suppresses dust during loading and unloading.

Baichy Collaboration: Can integrate third-party dust removal equipment or provide EPC solutions.

11. Silo/storage tank: Temporarily store finished coke, anti-oxidation design is required.

12. Quantitative packaging machine: used for bagging or ton bag packaging of coke powder.

Key points for equipment selection for coke processing projects

• Raw material characteristics: coke has high hardness (Mohs hardness 3-4) and is fragile, so wear-resistant steel and low-speed crushers are required.

• Finished product requirements: Metallurgical coke needs to strictly control particle size, and screening equipment needs to be accurately graded; coke powder processing needs to strengthen dust removal.

• Capacity matching: Select equipment model according to project scale (such as 100-1000 tons/hour) to avoid "big horse pulling a small cart".

• Automation level: Baichy can provide intelligent control system (PLC/DCS) to achieve remote monitoring and fault warning.

Baichy Heavy Industry's adaptability analysis

• Complete core equipment for crushing, screening and conveying, and EPC general contracting experience can cover production line design.

• Wear-resistant technology (such as high manganese steel lining) extends equipment life.

Recommended configuration process for coke processing projects

• Raw material preparation → Vibrating feeder → Jaw crusher (coarse crushing)

• Medium and fine crushing → Cone crusher → Vibrating screen (grading)

• Finished product transportation → Belt conveyor → Silo/packaging system

• Environmental protection support → Fully enclosed + dust collector