Heavy hammer crusher and high-efficiency fine crusher are two common crushing equipment. The main differences are reflected in the working principle, applicable scenarios, crushing effect and equipment structure. The following are their core differences:

Use and crushing stage of heavy hammer crusher and high-efficiency fine crusher

Use: Mainly used for coarse crushing or medium crushing, suitable for processing large and high-hardness materials (such as limestone, bluestone, construction waste, etc.).

Features: Through the high-speed rotating heavy hammer head directly impacting the material, the "one-time forming" coarse crushing effect is achieved, which can replace the combination of jaw crusher + impact crusher.

High-efficiency fine crusher

Use: Designed for fine crushing, suitable for secondary crushing after medium crushing or direct production of fine aggregates (such as sand making, cement clinker, coal gangue, etc.).

Features: Through multi-stage crushing chamber and special structural design, multiple collisions and grinding of materials are achieved, and the output particle size is finer and more uniform.

Heavy hammer crusher and high-efficiency fine crusher structure and working principle

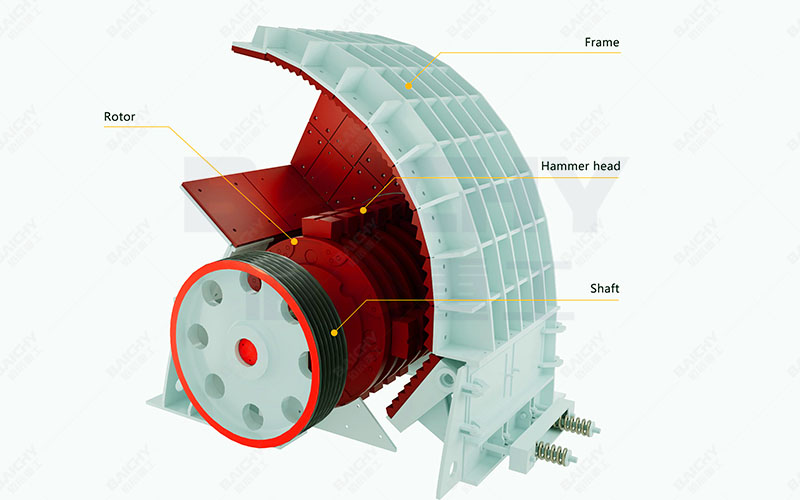

Heavy hammer crusher

Structure: single rotor design, heavy hammer head, small number, hammer head and rotor rigid connection, strong impact force.

Principle: After the material enters the crushing chamber, it is crushed by the high-speed rotating hammer head, and the discharge particle size is controlled by the grate screen.

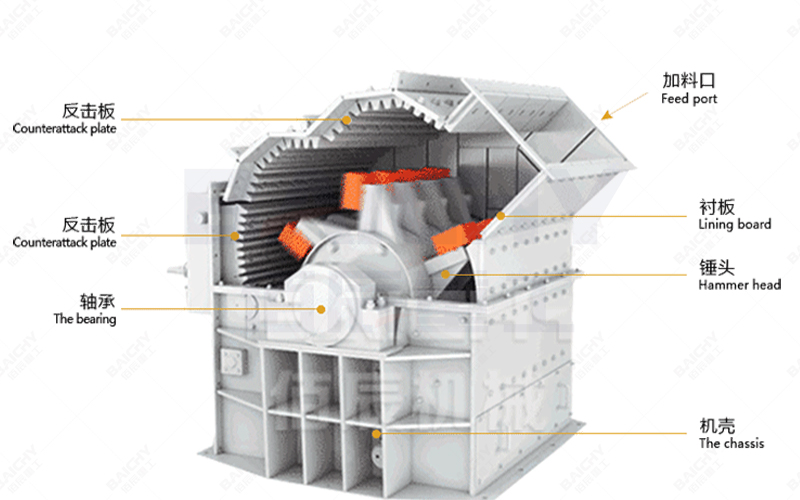

High-efficiency fine crusher

Structure: usually adopts double rotor or optimized single rotor design, with a large number of hammer heads and light weight, and cooperates with impact liner or grate plate.

Principle: The material undergoes multiple impacts, collisions and grinding in the crushing chamber, and the fineness of the finished product is controlled by adjusting the liner gap or the grate plate aperture.

Heavy hammer crusher and high-efficiency fine crusher Discharge particle size and finished product quality

Heavy hammer crusher

Discharge particle size: coarse, generally between 5-35mm, suitable for the production of coarse aggregate.

Finished product shape: more angular particles, higher needle-like content

High-efficiency fine crusher

Discharge particle size: finer, can reach 0-5mm (similar to the effect of sand making machine), and the particle size distribution is uniform.

Finished product shape: round particles, low needle-like content, suitable for high-standard building materials production.

Heavy hammer crusher and high-efficiency fine crusher Processing capacity and energy consumption

Heavy hammer crusher

Advantages: large processing capacity per machine, suitable for high-yield coarse crushing needs, relatively low energy consumption.

Limitations: weak fine crushing capacity, if used for fine crushing, the efficiency will decrease and the wear will increase.

High-efficiency fine crusher

Advantages: high fine crushing efficiency, lower unit energy consumption, suitable for scenes with high requirements for finished product fineness.

Limitations: easy to block when handling large pieces of material, need to be used with coarse crushing equipment.

Life and maintenance of wear-resistant parts of heavy hammer crusher and high-efficiency fine crusher

Heavy hammer crusher

The hammer head wears faster (due to direct impact on hard materials), the replacement cycle is short, but the structure is simple and maintenance is convenient.

High-efficiency fine crusher

Combined hammer head or alloy wear-resistant material is used, which has a longer service life; however, there are many vulnerable parts such as internal lining plates and grate plates, and the maintenance frequency may be higher.

Typical application scenarios of heavy hammer crusher and high-efficiency fine crusher

Heavy hammer crusher

Mine coarse crushing, construction waste treatment, limestone crushing, etc.

Case: directly crushing materials with a side length of 500mm to less than 30mm.

High-efficiency fine crusher

Machine-made sand production, cement plant clinker fine crushing, comprehensive utilization of coal gangue, etc.

Case: further crushing 20-30mm gravel to 0-5mm sand.

Recommendations for selecting heavy hammer crusher and high-efficiency fine crusher

Choose a heavy hammer crusher: if the raw material block size is large (>300mm), coarse crushing or medium crushing is required, and the finished product particle size requirement is not high.

Choose an efficient fine crusher: if you need to further crush the medium-crushed material (such as 20-50mm) to less than 5mm, or directly produce high-quality sand and gravel aggregates.

Depending on specific production requirements (such as material hardness, feed size, production capacity and finished product requirements), the two can also be used in combination to form a multi-stage crushing process.