PE600×900 jaw crusher, as a primary crusher, is widely used in mining, building materials and other fields. The following is a detailed introduction to the equipment:

Basic parameters of PE600×900 jaw crusher

• Equipment model: PE600×900

• Feeding port size: 600×900 mm

• Feeding particle size: ≤500 mm

• Discharging particle size: Adjustment range 65160 mm (some say 80160 mm)

• Production capacity: The production capacity of equipment from different manufacturers is different, ranging from 50180t/h, and there are also high-performance equipment that can reach 180455t/h

• Motor power: usually equipped with Equipped with 75kw or 90kw motor, the greater the power, the higher the crushing capacity

• Eccentric shaft speed: generally 250r/min

• Total weight: about 17t (may vary slightly from manufacturer to manufacturer)

• Dimensions: roughly 2190×2206×2300mm (may vary from manufacturer to manufacturer)

PE600×900 jaw crusher equipment features

• Simple structure, reliable operation: PE600×900 jaw crusher has a simple structure, easy parts replacement, simple equipment maintenance, and reliable operation.

• Large crushing ratio, uniform product size: The equipment has a large crushing ratio and uniform product size, which can meet the particle size requirements of different users.

• Low noise, less dust: The equipment has low noise and less dust emission during operation, which is beneficial to environmental protection.

• Energy saving and high efficiency: The equipment has significant energy saving effect, single machine energy saving can reach 15%~30%, and the system energy saving is more than doubled.

• Large discharge port adjustment range: The gasket-type discharge port adjustment device is reliable and convenient, with a large adjustment range, which increases the flexibility of the equipment.

• Deep feed inlet: allows stones to pass smoothly, and the equipment's vulnerable parts are made of highly wear-resistant materials, so it can crush stones of various hardness.

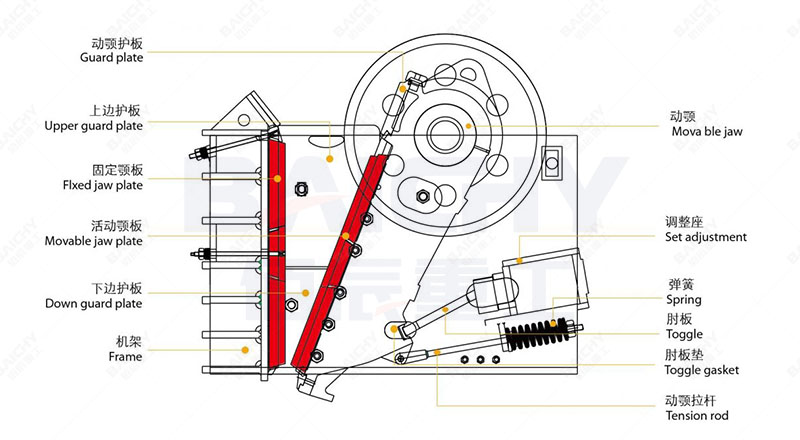

Working principle of PE600×900 jaw crusher

The working principle of PE600×900 jaw crusher is a cam-type extrusion type. The motor drives the belt and pulley, and the movable jaw moves up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw increases, thereby pushing the movable jaw plate to approach the fixed jaw plate. At the same time, the material is squeezed, rubbed, and crushed in multiple ways; when the movable jaw descends, the angle between the toggle plate and the movable jaw decreases, and the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and spring. At this time, the crushed material is discharged from the lower opening of the crushing chamber. As the motor rotates continuously, the movable jaw of the crusher performs periodic crushing and discharging to achieve mass production.

PE600×900 jaw crusher application field

PE600×900 jaw crusher is mainly used for primary crushing operations in mining, building materials and other fields. It is suitable for crushing materials of various hardness such as quartz, calcium stone, granite, basalt, limestone, diabase, iron ore, etc.

As a primary crusher with superior performance and simple structure, PE600×900 jaw crusher has broad application prospects in mining, building materials and other fields.