Gypsum powder making machine is a special equipment for producing gypsum powder. It has various types and models. Different equipment can be selected according to different production needs. The following is a detailed introduction to gypsum powder making machine:

Main types of gypsum powder making machine

Common gypsum grinding machines include Raymond mill, vertical mill, etc.

Raymond mill: The gypsum raw material is crushed into fine powder by the rolling action of the grinding roller and the grinding ring. It has the advantages of simple structure, convenient operation and low maintenance cost.

Vertical mill: The gypsum is crushed and ground by the rotating motion of the grinding disc and the grinding roller. It has the advantages of high grinding efficiency, low energy consumption and small footprint.

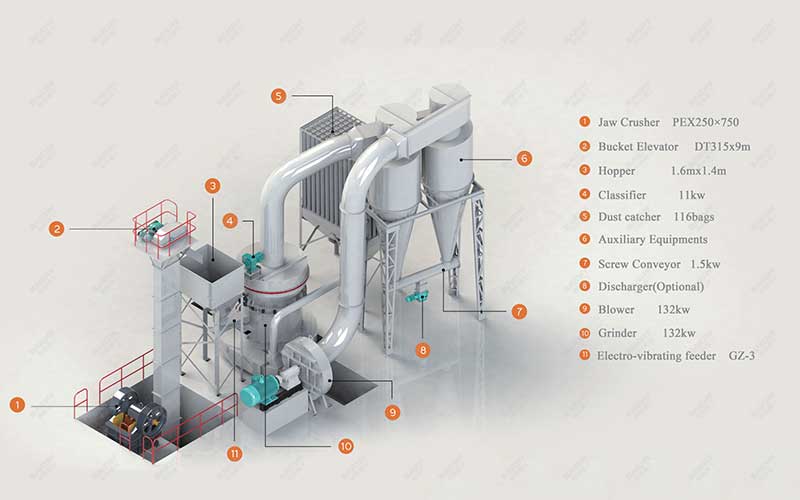

Gypsum powder production line equipment:

Gypsum powder production line usually includes crusher, dryer, grinder, classifier, dust collector and other equipment.

These equipment work together to crush, dry, grind, classify and other processes of gypsum raw materials, and finally produce gypsum powder that meets the requirements.

Working principle of gypsum powder making machine

Take Raymond mill gypsum grinding machine as an example, its working principle is as follows:

• The motor drives the grinding disc to rotate through the reducer, and high-temperature hot air enters the mill from the air inlet.

• The gypsum raw material falls into the center of the grinding disc from the discharge port and moves to the edge of the grinding disc under the action of centrifugal force.

• The gypsum raw material is crushed by the grinding roller when passing through the annular groove on the grinding disc.

• The crushed material continues to move to the edge of the grinding disc until it is carried by the high-speed hot air flow at the wind ring.

• The attached water and crystal water carried by the gypsum fine powder are removed in the air flow.

• When the material in the air flow passes through the separator, the coarse powder falls on the grinding disc and is re-grinded, and the qualified fine powder is discharged from the mill with the air flow.

• The gypsum powder collected and cooled in the dust collection device of the system is the product.

Price and purchase of gypsum powder making machine

The price of gypsum powder making machine varies depending on factors such as model, output, and brand.

Generally speaking, the higher the output, the higher the price of the equipment.

The specific price needs to be customized and selected according to the actual needs and budget of the customer.

Purchase suggestions:

• Clear production needs: Determine the required equipment model and output according to production scale, product requirements and other factors.

• Understand equipment performance: Understand the performance parameters, working principle and other information of the equipment by consulting product manuals and consulting manufacturers.

• Choose well-known brands: Choose well-known brand equipment with good reputation and after-sales service to ensure the quality and reliability of the equipment.

• Consider after-sales service: Choose manufacturers that provide perfect after-sales service so that they can get technical support and maintenance services in time during use.

Maintenance and maintenance of gypsum powder making machine

Regular inspection: Regularly inspect and maintain the equipment to ensure the normal operation of the equipment and extend its service life.

• Cleaning and maintenance: Regularly clean the dust and dirt inside the equipment to avoid blockage and wear.

• Lubrication and maintenance: Lubricate and maintain the transmission parts of the equipment to reduce wear and failure.

• Pay attention to safety: Pay attention to safe operation during maintenance and maintenance to avoid accidents.

Gypsum powder making machine is one of the important equipment for producing gypsum powder. During the selection and use process, it is necessary to fully consider factors such as production needs, equipment performance, price, etc., and perform regular maintenance and care to ensure the normal operation of the equipment and extend its service life.