HGM micro powder mill is mainly suitable for non-flammable and non-explosive brittle materials with medium and low hardness (Mohs hardness ≤ 6), such as calcite, chalk, limestone, etc. Regarding the spare parts of the HGM micro powder mill, the following are some core components and possible spare parts:

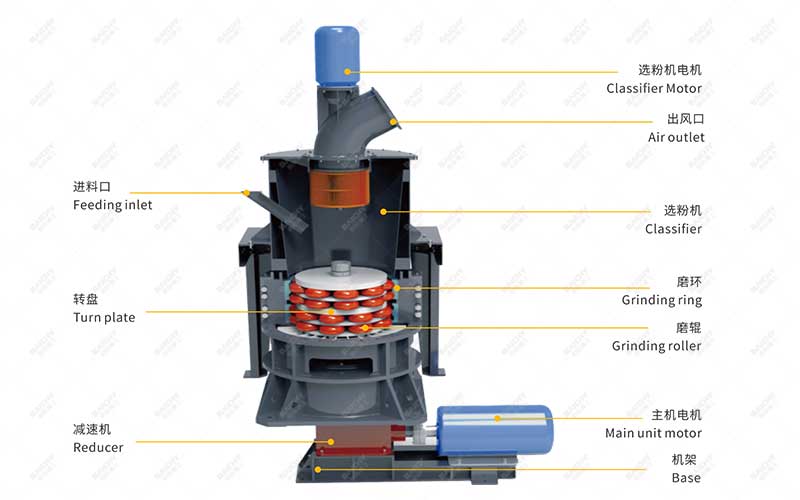

1. Grinding roller and grinding ring:

The grinding roller and grinding ring are the key wear parts of the HGM micro powder mill, which directly contact the material and crush it.

Due to long-term friction with the material, the grinding roller and grinding ring will gradually wear, so they need to be inspected and replaced regularly.

These spare parts are usually forged with special materials to improve wear resistance and service life.

2. Roller pin and turntable:

The roller pin is used to connect the grinding roller and the turntable to ensure that the grinding roller rolls correctly in the grinding ring raceway.

The turntable is responsible for driving the grinding roller to rotate and is a key component for transmitting power.

These spare parts need to have good wear resistance and strength to ensure the stable operation of the equipment.

3. Bearings and seals:

Although the design of the HGM micro powder mill reduces the use of rolling bearings, bearings may still be used in some models or parts.

Bearings and seals are important components to prevent material leakage and keep the inside of the equipment clean.

It is necessary to regularly check the lubrication of the bearings and the sealing performance of the seals, and replace damaged spare parts in time.

4. Pulse dust collector and muffler:

The pulse dust collector is used to reduce dust pollution and ensure the cleanliness of the working environment.

The muffler is used to reduce the noise generated during the operation of the equipment, which meets environmental protection requirements.

These spare parts need to be regularly maintained and replaced to ensure their normal operation and environmental protection effect.

5. Other spare parts:

Depending on the specific model and configuration of the HGM micro powder mill, other spare parts may also be included, such as the hammerhead of the hammer crusher, the conveyor belt of the bucket elevator, etc.

These spare parts also need to be regularly inspected and maintained to ensure the overall performance and stability of the equipment.

To ensure the long-term stable operation of the HGM micro powder mill, it is recommended that users establish long-term cooperation with equipment manufacturers or professional spare parts suppliers to obtain spare parts support and technical services in a timely manner. At the same time, users should also formulate a reasonable spare parts replacement plan based on the actual use of the equipment to reduce downtime and maintenance costs.