The spiral classifier, also known as the spiral grading screen or spiral sand washer, is one of the equipment for mineral processing. It mainly uses the difference in the settling speed of solid particles in the liquid to classify solid-liquid mixed materials (such as slurry) according to the particle size and specific gravity.

Working principle of spiral classifier

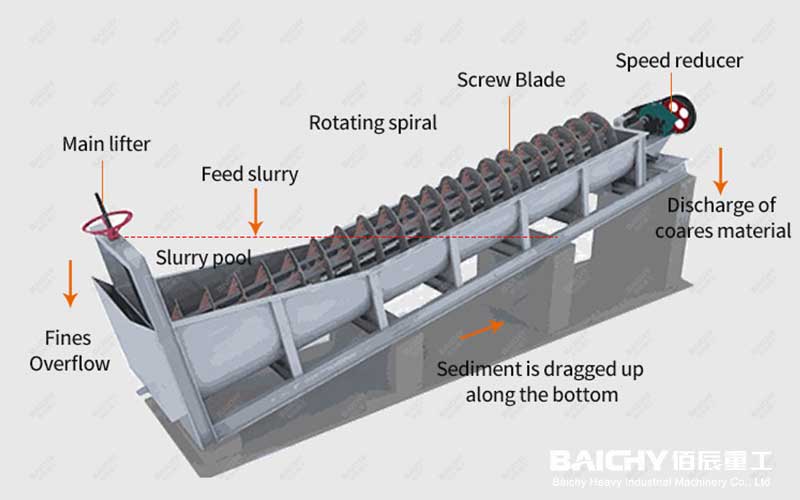

The working principle of the spiral classifier is based on the material rotating along the spiral trough under the push of the spiral blade, and at the same time being subjected to the combined action of gravity, centrifugal force and water flow (or air) to achieve the classification and separation of materials. In wet classification, the material is mixed with water and enters the spiral classifier. Through the rotation of the spiral blade and the flushing of water, light and fine materials (such as fine sand and mud) overflow from the top of the trough with the water flow and become overflow products; while heavy and coarse materials (such as coarse sand and stone) are discharged along the bottom of the trough under the push of the spiral blade to achieve effective separation. Dry classification mainly achieves the classification purpose through the blowing of air flow and the pushing action of spiral blades.

Structural composition of spiral classifier

The spiral classifier is mainly composed of transmission device, spiral body, trough body, lifting mechanism, lower support (bearing) and discharge valve.

1. Transmission device: It is composed of motor, reducer, cylindrical gear pair and bevel gear.

2. Spiral body: It is the core component of spiral classifier, which is composed of spiral shaft and spiral blade. The spiral shaft is generally a hollow shaft with bearings installed at both ends. The spiral blade is welded on the spiral shaft. Its shape and pitch are designed according to different classification requirements and are used to push the material to move.

Types of spiral classifier:

1. Single spiral classifier: It has only one spiral body, simple structure, small footprint, and is suitable for occasions with small processing volume.

2. Double spiral classifier: It is suitable for occasions with large processing volume and high requirements for classification accuracy, such as pulp classification operations in large ore dressing plants.

Features of spiral classifier

1. Simple structure: The spiral classifier is mainly composed of spiral body, trough body, transmission device and other components. It has a compact structure, relatively simple manufacturing process, and is easy to install and maintain.

2. Reliable operation: The connection between the components is firm, the operation is stable, and it is not easy to fail. The spiral body and the trough body are made of wear-resistant materials, with a long service life and can adapt to harsh working environments.

3. Convenient operation: The operation process is simple and easy to master. By adjusting the parameters such as the speed of the spiral body, the lifting height, and the opening of the discharge valve, the classification accuracy and processing volume can be easily controlled to meet different production requirements.

4. High classification efficiency: The spiral classifier can effectively separate the coarse and fine particles in the slurry. The classification efficiency is generally around 60%~80%. For some special classification processes, the classification efficiency can even reach more than 90%.

5. Strong adaptability: The spiral classifier can handle materials of various particle sizes and specific gravities, and has good adaptability for the classification of various materials such as ore, coal, sand and gravel.