The popular online searches about jaw crushers are mainly concentrated in the following aspects. The search keywords are: "jaw crusher working principle animation", "jaw crusher structure diagram", "the role of the moving jaw and the static jaw", "how to adjust the jaw crusher discharge particle size"; popular reasons: users want to intuitively understand the operation mechanism of the equipment, especially novices or technicians who need maintenance.

Working principle of jaw crusher

1. Core principle: crushing materials through the periodic extrusion movement of the moving jaw and the static jaw.

2. Feeding: the material falls into the crushing chamber from the top feed port.

3. Extrusion crushing: the motor drives the eccentric shaft to rotate, driving the moving jaw to approach the static jaw, applying pressure to the material to crush it.

4. Discharge: the crushed material is discharged from the bottom discharge port under the action of gravity.

5. Movement characteristics: the moving jaw moves in a "quasi-elliptical" trajectory, which can both efficiently crush and avoid blockage.

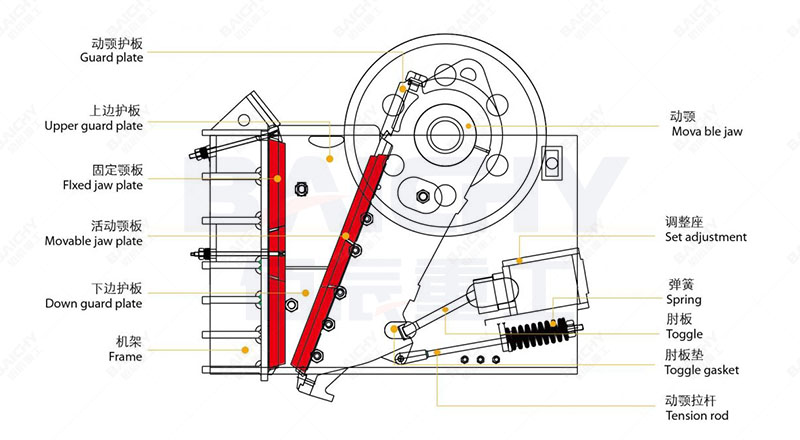

Core structure of jaw crusher

1. Frame: supports the whole machine, made of high-strength steel plate welding or cast steel.

2. Static jaw: fixed on the frame, serving as the crushing reference surface.

3. Moving jaw: driven by the eccentric shaft, the active crushing component that generates extrusion motion.

4. Jaw plate: a high-manganese steel wear-resistant lining with a wavy or toothed surface, directly in contact with the material.

5. Eccentric shaft and connecting rod: convert the motor's rotary motion into the reciprocating motion of the moving jaw.

6. Wedge adjustment: adjust the width of the discharge port by adding or removing gaskets.

7. Hydraulic adjustment: some models support rapid adjustment of hydraulic cylinders.

8. Safety device: protect the equipment by breaking the toggle plate or hydraulic system when overloaded.

Comparison of the functions of the movable jaw and the static jaw

Parts Function Motion state Wear characteristics

Moving jaw Actively squeezes materials and transmits mechanical energy Periodic reciprocating motion Wear is concentrated on the lower part (maximum area of extrusion stroke)

Static jaw Provides reaction force and fixes the crushing reference surface Completely stationary Wear is uniform, and the service life is usually longer than that of the movable jaw

How to adjust the discharge particle size?

1. Adjustment method:

Mechanical adjustment: Adjust the number of gaskets at the rear of the frame after shutdown (increase the gasket → the discharge port becomes smaller → the discharge is finer).

Hydraulic adjustment: Modern models can operate the hydraulic system in real time through the control panel.

2. Precautions:

After adjustment, check the parallelism of the jaw plate to avoid eccentric wear.

The particle size adjustment range must be within the equipment calibration range (generally ±10% of the nominal discharge port).

Particle size detection: Use a sifter or caliper to measure the crushed product and adjust it until it meets the standard.

Extension of user FAQ

Maintenance points: Regularly check the jaw plate fastening bolts and lubricate the eccentric shaft bearing (fill once every 8 hours).

Productivity optimization: Control the feed particle size not to exceed 80% of the maximum size allowed by the equipment.

Fault handling: If abnormal vibration occurs, first check whether the toggle plate is broken or the foundation bolts are loose.