The requirements for granite crushers mainly include the following aspects:

1. Efficient crushing capacity:

• Granite is a hard rock, so the crusher needs to have a strong crushing capacity to cope with materials with high hardness and wear resistance.

• The crusher is required to be able to efficiently crush large pieces of granite to the required particle size to meet production needs.

2. High wear resistance and durability:

• Due to the high hardness of granite, the components of the crusher (such as crushing teeth, crushing chamber, etc.) need to have good wear resistance to extend the service life of the equipment.

• The overall structure of the equipment also needs to have sufficient strength and stability to ensure that it will not deform or damage under long-term high-load operation.

3. Good discharge performance:

• The crusher is required to be able to discharge the crushed materials smoothly to avoid blockage or jamming.

• Reasonable design of discharge port and discharge system to ensure smooth flow and discharge of materials.

4. Low noise and environmental protection:

• The crusher should generate low noise during operation to reduce the impact on operators and the surrounding environment.

• The equipment should have good sealing and dust removal facilities to reduce dust emissions and meet environmental protection requirements.

5. Easy operation and high degree of automation:

• The operation of the crusher should be simple and easy to understand, and convenient for operators to operate and maintain.

• The equipment should have a high degree of automation, be able to achieve remote control and monitoring, and improve production efficiency and safety.

6. Easy maintenance and high reliability:

• The equipment should be reasonably designed to facilitate daily maintenance and maintenance.

• Key components and wearing parts should have a long service life to reduce replacement frequency and maintenance costs.

• The equipment should have high reliability, be able to operate stably for a long time, and reduce downtime.

7. Strong adaptability:

• Since the properties and particle size of granite may vary, the crusher needs to have a certain adaptability and be able to handle granite of different properties and particle sizes.

• The equipment should have the function of adjusting the crushing particle size to meet different production needs.

Granite crushers need to have high-efficiency crushing capacity, high wear resistance and durability, good discharge performance, low noise and environmental protection, easy operation and high automation, easy maintenance and high reliability, strong adaptability and high safety. These requirements will help improve the performance and production efficiency of the equipment and reduce maintenance costs and safety risks.

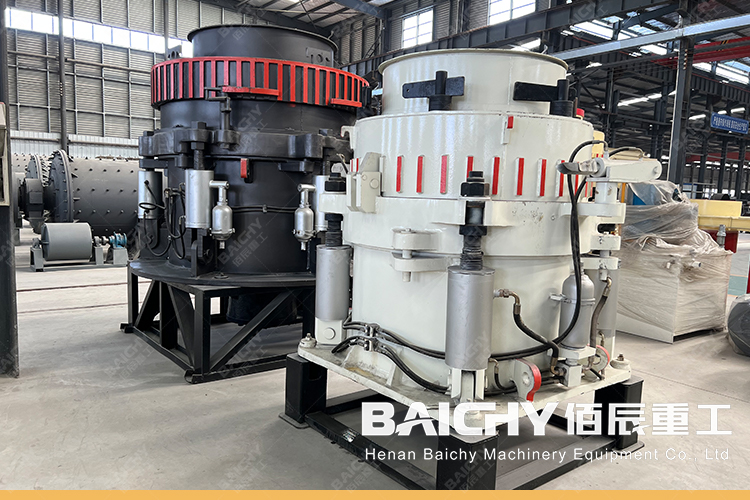

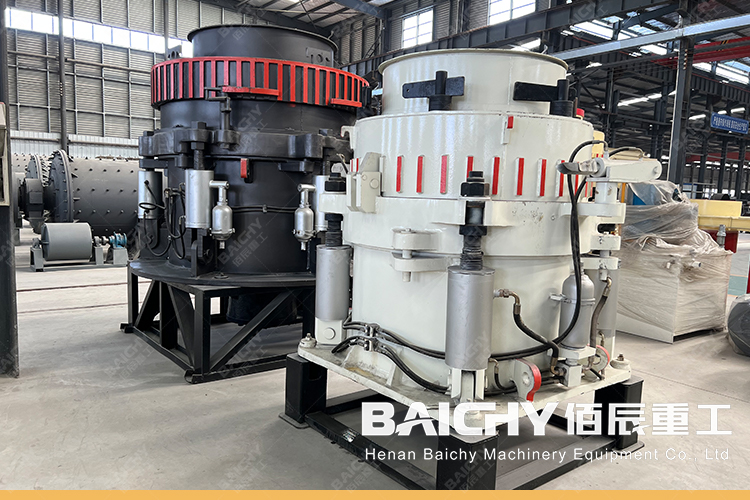

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.