In response to the demand for 250-300tph medium-sized hard rock crushing equipment, the following is a detailed recommendation and introduction:

Overview of equipment configuration

Medium-sized hard rock crushing equipment is mainly used to process rocks with higher hardness, such as granite, basalt, etc. In order to meet the production needs of 250-300tph, the equipment configuration should ensure high efficiency, stability, and durability.

Main equipment components

Jaw crusher:

Selection: PE900X1200 jaw crusher or similar models are recommended as primary crushing equipment, responsible for crushing large pieces of hard rock into smaller particles.

Features: large crushing ratio, simple structure, stable operation, and easy maintenance.

Output: According to material characteristics and operating conditions, it can meet the production needs of 250-300tph.

Cone crusher:

Selection: HP300 or similar models are recommended as secondary crushing equipment to further crush the materials crushed by the jaw crusher to the required particle size.

Features: Suitable for crushing materials of medium hardness, high crushing efficiency, and uniform product particle size.

Output: Cooperate with jaw crusher to ensure that the overall production process meets the production demand of 250-300tph.

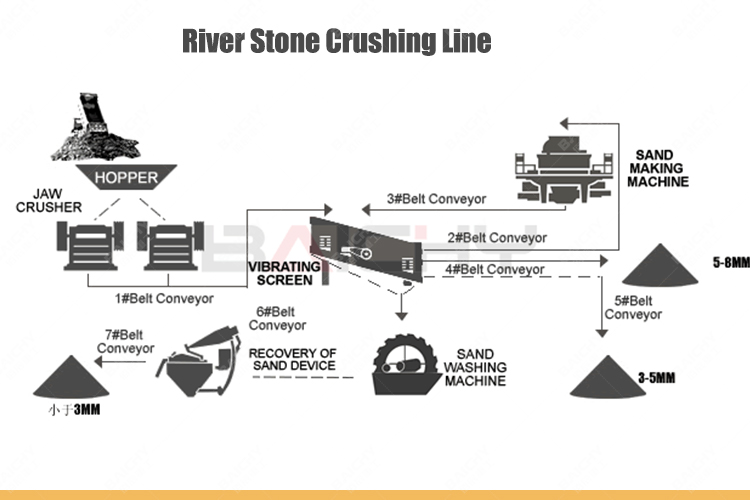

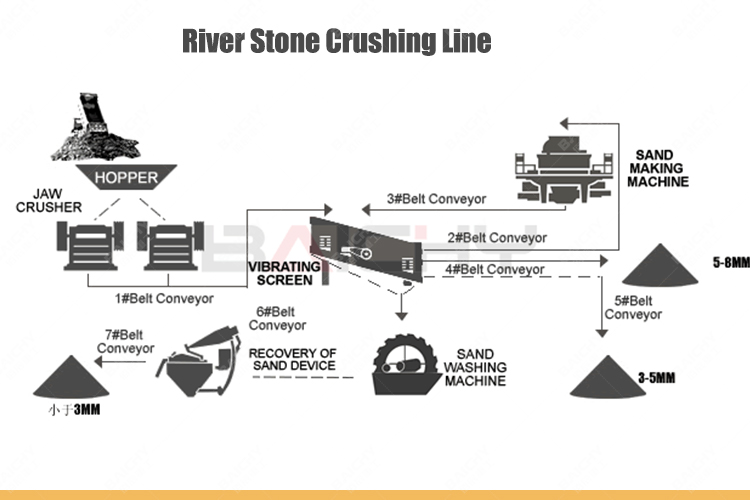

Vibrating screen:

Selection: A 3YK series vibrating screen is recommended to screen the crushed materials, and separate the finished materials that meet the requirements and the bulk materials that need to be returned to the crusher for re-crushing.

Features: High screening efficiency and large processing capacity. The screen aperture can be adjusted according to the need to obtain products of different particle sizes.

Conveying equipment:

Including a belt conveyor, etc., used to connect the crushing equipment and vibrating screen at all levels to achieve efficient and continuous transportation of materials.

Additional configuration

Dust removal equipment: According to environmental protection requirements, dust removal equipment can be equipped to reduce dust emissions during the production process.

Electronic control system: An advanced electronic control operating system is adopted to ensure the safe and reliable operation of the entire production line.

Performance characteristics

High efficiency: The overall configuration is reasonable, and the processing capacity of crushing equipment at all levels matches each other to ensure an efficient and continuous production process.

Stability: The equipment has a solid structure, stable operation, easy maintenance, and reduced failure rate.

Flexibility: The equipment configuration can be adjusted according to material characteristics and production requirements to meet the crushing needs of different occasions.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.